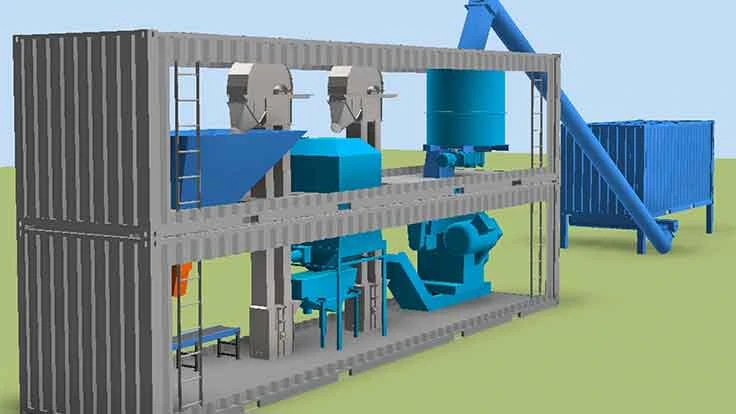

Vecoplan Midwest has introduced the containerized pellet plant (CPP). The company calls the new plant a “quick, easy and affordable solution for 1-to-2-ton-per-hour pellet production.”

A turnkey pellet production plant housed in standard shipping containers, the CPP is designed, built and shipped from Vecoplan Midwest's New Albany, Indiana, location. It comes complete with controls, and arrives on two semi trucks.

All the customer needs is a flat 40-foot surface and electric feed to the main panel. A crane is used to stack the containers and the CPP can be up and running production within 4 hours.

The CCP easily adapts to most existing trailer load out systems, alleviates the need for expensive buildings and is the perfect for processing, wood, biomass, feed products, manures -- most anything that needs to be pelleted, according to the company. The plant can be relocated in a very short time should the need arise.

Vecoplan Midwest is available to provide after sales service and parts as well as on-site operator training.

Latest from Construction & Demolition Recycling

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- Greenwave raises revenue but loses money in Q2 2025

- Recycled steel prices hold steady

- John Deere launches ‘Building America’ excavator contest

- Triumvirate Environmental acquires Environmental Waste Minimization

- Coastal Waste & Recycling expands recycling operations with Machinex

- Reconomy acquires German-based GfAW