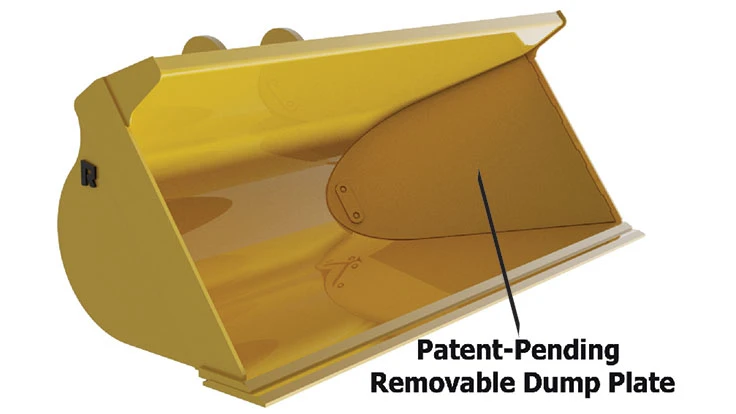

Rockland Manufacturing, Bedford, Pennsylvania, has recently introduced its SDB side dump bucket. The SDB side dump bucket features a patent-pending removable dump plate designed to transform the side dump bucket into a general purpose bucket. The option to unload material either conventionally or laterally at a 45-degree angle is made to increase flexibility, efficiency and reduce cost.

The SDB’s dump plate can be removed anywhere without cutting or welding, the company says. The dump plate also functions as a wear part, reducing the need for expensive rebuilds and increasing the total life of the side dump bucket.

All Rockland SDB side dump buckets are powered by a dual-cushioned cylinder that designed to provide a safe, smooth and quiet operation. The entire side dump bucket body and dump plate is crafted from an alloy plate designed to make it wear and abrasion-resistant, even with frequent contact with asphalt and other hard surfaces.

The SDB’s dump plate can be removed anywhere without cutting or welding, the company says. The dump plate also functions as a wear part, reducing the need for expensive rebuilds and increasing the total life of the side dump bucket.

All Rockland SDB side dump buckets are powered by a dual-cushioned cylinder that designed to provide a safe, smooth and quiet operation. The entire side dump bucket body and dump plate is crafted from an alloy plate designed to make it wear and abrasion-resistant, even with frequent contact with asphalt and other hard surfaces.

Latest from Construction & Demolition Recycling

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- Greenwave raises revenue but loses money in Q2 2025

- Recycled steel prices hold steady

- John Deere launches ‘Building America’ excavator contest

- Triumvirate Environmental acquires Environmental Waste Minimization

- Coastal Waste & Recycling expands recycling operations with Machinex

- Reconomy acquires German-based GfAW

- CommanderAI launches HaulerCentral database