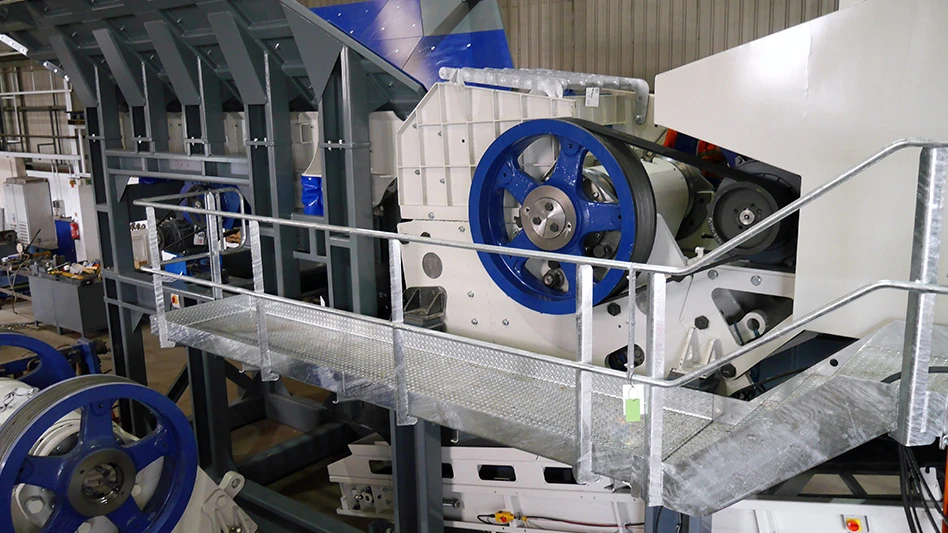

Photo courtesy of Quarry Manufacturing & Supplies

Quarry Manufacturing & Supplies (QMS) has revamped its jaw crushing offering to deliver low-cost-per-ton production for its customers.

The JB Series is designed and engineered to meet the primary crushing needs of customers in the mining, quarrying and recycling industries. QMS says the line is driven by industry knowledge, working in close association with its customers to provide what it believes to be the lowest-cost-per-ton primary crushing on the market today.

The JB Series of jaw crushers is available as a base unit or part of modular plant. Jaw sizes available range from 930 by 580 millimeters (mm) to 1,400 by 1,200 mm, producing a closed side setting ranging from 60 mm to 250 mm and scalped production up to 1,500 tons per hour.

“The QMS JB Series of jaw crushers has provided customers throughout the world with a state-of-the-art primary jaw crushing solution,” QMS Managing Director Jonathan Beck says. “However, even the best can be improved. Our aim in redesigning the JB Series is to improve productivity, efficiency and accuracy. In doing this we have designed a jaw crusher that uses energy more efficiently, is able to produce more tons of crushed material per hour and fit seamlessly into a production flow.”

England-based QMS says to minimize operational costs, it has developed efficient power management strategies to help reduce energy consumption. The JB Series also integrated intelligence into the design so the plant’s operations can reduce reliance on its workforce.

The JB Series redesign is the result of various studies carried out by QMS research and development team, including fatigue calculations, bench testing and theoretical calculations. QMS says the modular, non-welded frame boasts a state-of-the-art design with two hot-rolled steel side plates joined to high-quality cast steel frames with the absence of stress inducers to provide excellent durability against shock loads.

QMS also designed the JB Series to hydraulically adjust the crusher setting quickly and efficiently without having to handle bulky shims. The company says its wedge setting adjustment system is proven to clear the crusher’s cavity should it stall under load.

“The entire design of the JB Series is maintenance friendly and built to deal with the most demanding of operating conditions,” Beck says. “This means we believe that we have a primary jaw crusher that will help contribute to the lowest cost per ton production.”

Latest from Construction & Demolition Recycling

- John Deere announces plans to open 2 new U.S. facilities

- Company incorporates safety, cost of ownership considerations in demo equipment offerings

- Metso adds Florida to Mellot’s distributor territory

- Maverick Environmental Equipment opens Detroit area location

- Nucor finishes 2025 with 14 percent earnings decline

- G2 Consulting Group acquires Construction Testing Services

- CBI to showcase 5900T horizontal grinder at ConExpo 2026

- Steel Dynamics reports 2025 financial results