Application specifications

A large regional concrete recycler required rebar removal from crushed concrete. An additional requirement was that the rebar be discharged far enough away from the concrete that it would not drop back into the cleaned concrete.

- Crushed concrete, 6-inch maximum lump size

- Conveyor belt 54-inch wide traveling 260–300 FPM

- 12-inch product depth

- ¼-inch to ½-inch diameter re-bar up to 10’ long

The Custom IMI Solution

Industrial Magnetics was able to achieve the customers’ goal through a custom engineered combination of magnets. This consisted of placing an electromagnet and permanent magnet end-to-end. The electromagnet yielded a deep reach for the preexisting structures setup, and the permanent magnet held the rebar and transferred it to a safe distance from the purified product. The engineering team at Industrial Magnetics is ready to think outside the box to provide custom solutions for complex application requirements.

- Self-cleaning suspended electromagnet, oil cooled

- Electromagnet measured 72 inches square

- Two permanent plate magnet extensions to carry collected rebar away from the cleaned concrete

- Extra heavy duty vulcanized ¾-inch thick self-cleaning belt

- Stainless steel cleats to prevent rebar from rolling back into the magnetic field

- Special stainless steel belt guards to prevent metal retention on the side of the magnet

- Overall length: 24 feet, 2 inches

Learn more about IMI’s construction and demolition recycling equipment.

Latest from Construction & Demolition Recycling

- MB Crusher at ConExpo

- Suspended magnet options galore

- European Demolition Association selects Dublin for annual convention

- Are you missing out on money?

- Oregon shopping center could be nearing demolition

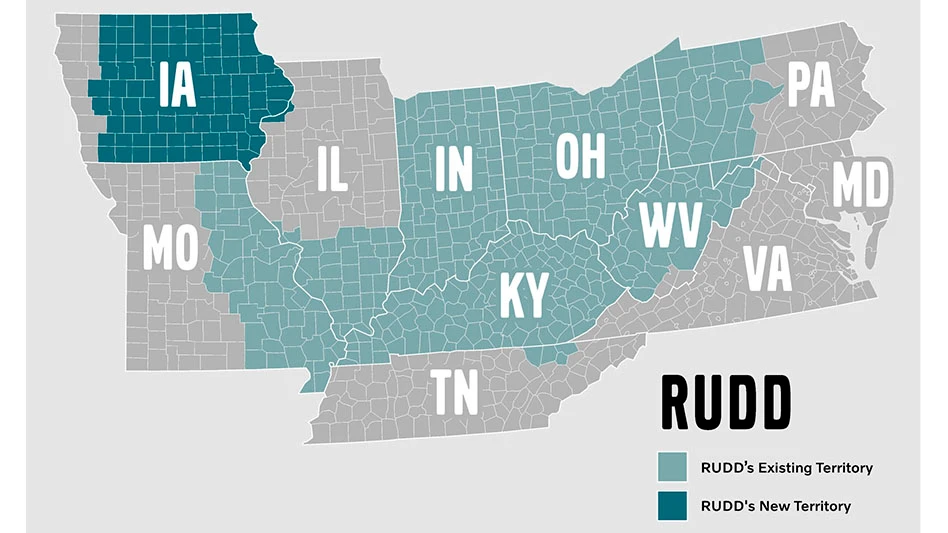

- Fraser Valley Junk Solutions expands service availability

- Carolinas AGC honors 2025 Pinnacle, Construction Excellence award recipients

- Viably adds Maverick Equipment as dealer