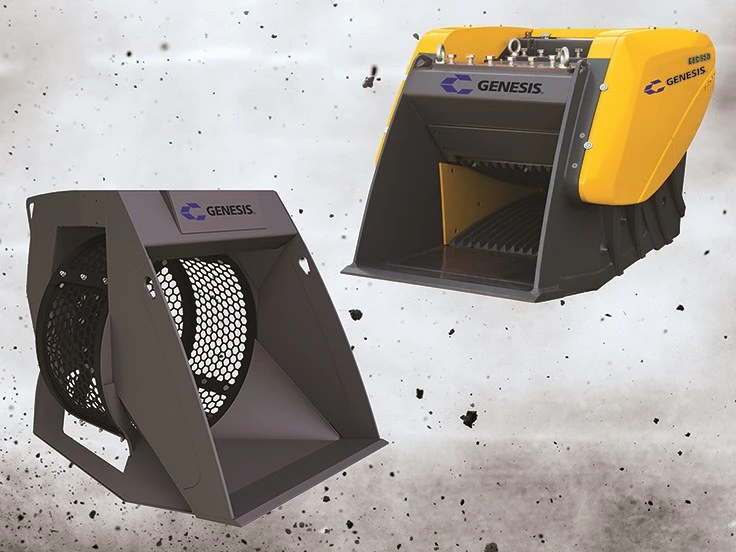

Genesis Attachments, Superior, Wisconsin, has announced the introduction of the GBS bucket screener and GBC bucket crusher. According to the company, the equipment reduces material delivery and removal costs and minimizes the need to purchase new aggregate.

The GBS has been designed to provide a mobile and cost-effective solution for sizing natural rock and recycling material on-site. The product works quickly and efficiently while occupying minimal space, according to Genesis. The extra-large drum has been designed to result in higher production, with individual replacement screens available in a range of standard mesh sizes, as well as custom sizes for prescreening and final classification. Genesis describes the gearbox as being maintenance-free, oversized and providing reliable and durable job site operation. Available in five models, the GBS fits machines ranging from 6,600 pound skid steers to 77,000 pound excavators.

Genesis describes the GBC as having a unique, aggressive figure-eight crushing motion that produces high-quality cubical product, enabling the aggregate to be reused on-site. Extra-large jaw plates have been designed to provide optimal performance and longer life, with Genesis indicating the GBC is built for durability with a large and robust casted jaw stock and Hardox frame. Available in four sizes to fit 22,000 to 77,000 pound excavators, the GBC's replaceable cheek plates and toggle seat and centralized lubrication system minimize maintenance, the company states.

Latest from Construction & Demolition Recycling

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- Greenwave raises revenue but loses money in Q2 2025

- Recycled steel prices hold steady

- John Deere launches ‘Building America’ excavator contest

- Triumvirate Environmental acquires Environmental Waste Minimization

- Coastal Waste & Recycling expands recycling operations with Machinex

- Reconomy acquires German-based GfAW

- CommanderAI launches HaulerCentral database