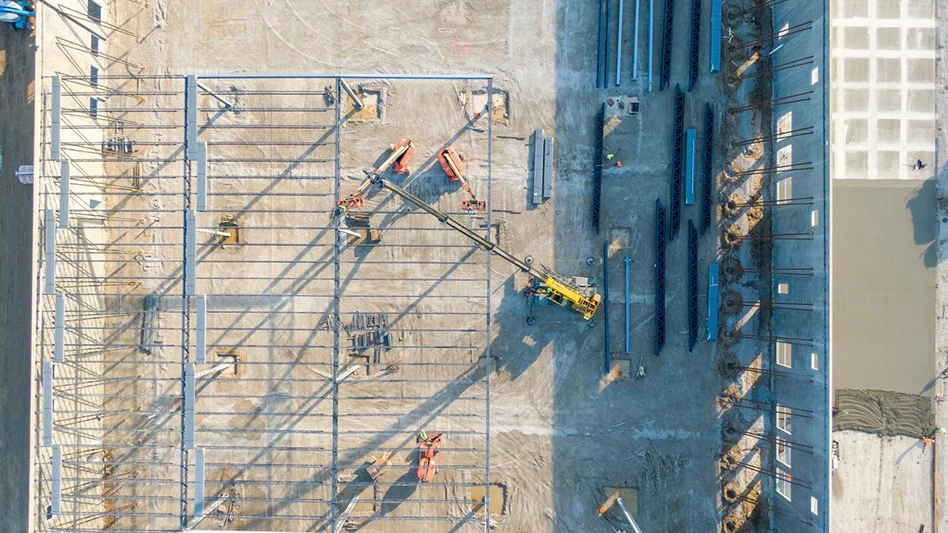

Photo courtesy of CDE Group

According to CDE Group, construction waste has been a growing problem on Long Island, New York. With each new project, the United Kingdom-based supplier of sand and aggregate washing systems with a United States office in Texas, says contractors are left with piles of excavation material and demolition debris, yet with landfill closures and rising disposal costs, removing this material has become increasingly expensive.

For Long Island-based Freehaven Materials, CDE says finding a solution to this problem meant staying competitive in a market where material costs were climbing and landfill space was disappearing.

RELATED: CDE publishes sustainability report | CDE launches symposium to redefine waste recycling

CDE says that to gain a competitive advantage in full-scope heavy-civil projects, Freehaven wanted a solution that would turn waste into reusable materials and realized that wet washing could provide that advantage and generate additional revenue.

In 2023, Freehaven formed a partnership with CDE and installed a 150-tons-per-hour wash plant on Freehaven’s site in Brookhaven, New York. “Suddenly, dirt was no longer an issue,” CDE says, adding that “dirt became dollars in the making.”

“We were paying fortunes to dispose of perfectly good material, and it just didn’t make sense,” says Tom Hayes of Freehaven. “With landfills closing and transport costs rising, we had to innovate to remain competitive. Partnering with CDE to install a wet processing plant allowed us to turn what was once waste into a valuable product. Now we’re recycling that material and putting it right back into local projects.”

The partnership was Freehaven’s first venture into wet processing. Previously, the company had relied on dry crushing and screening.

Creating materials for critical infrastructure

In early 2024, CDE says Freehaven commissioned its construction and demolition (C&D) waste recycling plant. Now, the company reports that the plant outputs a range of products, including ASTM C33-spec concrete sand for high-strength mixes, a clean fine sand and three grades of crushed stone ranging from pea gravel to larger aggregate.

CDE says these recycled aggregates already are finding their way into infrastructure projects across Long Island, including highways, bridges and roads.

“CDE’s reputation and dedication in designing and engineering high-quality wet processing solutions was integral in our decision making,” Hayes says. “We first met at ConExpo in 2023 and were impressed with their capabilities from the very beginning.

“Throughout the whole process, CDE provided us with a comprehensive consulting approach from engineering experts which in turn gave us the confidence we needed to get this plant up and running. We’re really proud of this plant.”

The wet processing solution

CDE says the modular wet processing system incorporates an R4500 primary scalping screen, an AggMax scrubbing and classification system, an EvoWash sand washing system, a counter flow classification unit (CFCU) density and sizing classification system, an AquaCycle thickener for primary stage water management and an AquaStore water tank.

Working together, the technologies wash and sort mixed loads of excavation soil through a multistage process.

CDE says the system removes organics, cleans clay-bound materials and scalps off overburden, “ensuring that only high-quality material is recovered.” The system then dewaters cleaned materials for use straight off the belts.

The AquaCycle and AquaStore integrated water recycling technology minimizes strain on local water sources by reducing the need for settling ponds, CDE says, which in turn reduces the overall environmental impact of the plant.

CDE adds that screens and classifiers then separate that material into specific gradations, producing sand and aggregates suitable for a variety of construction uses.

Plant performance

CDE says the plant also is equipped with its SmartTech application which enables customers to understand their plant’s performance, schedule maintenance and easily order parts.

Sensors fitted to across the plant provide up to 300 data points and continuously stream real-time, in-depth performance reports, providing a full and transparent overview of the health of the plant with a live feed that is accessible 24/7 through the SmartTech mobile app.

With this technology, CDE says Freehaven can monitor feed rates, and results from SmartTech data showed the plant consistently achieves an average feed of 171 tons per hour, exceeding the expected 150 tons per hour by 14 percent, resulting in 114 percent tons per hour utilization.

CDE says SmartTech also shows that the filter press cycle times are very low, with an average feed time of 13 minutes. Factoring in mechanical time, each cycle runs for approximately 28 minutes, allowing for higher material throughput and operational efficiency.

An opportunity

Joe Teahl, CDE’s business development manager, says, “There’s no shortage of construction waste on Long Island, and Freehaven recognized its potential. By investing in this solution, Freehaven Materials not only reduced its own costs but also created a sustainable local supply of aggregates.”

CDE says Freehaven’s success demonstrates that with the right technology, a challenge can be turned into an opportunity. The supplier claims that high disposal costs and virgin material scarcity are not problems unique to New York, but are emerging all over North America, and especially in the greater metropolis area as landfills fill up and natural sand and aggregates dwindle—making it difficult to source the needed materials, particularly at a time when organizations are trying to minimize transportation and CO2 emissions.

“Freehaven is setting the example here,” Teahl says. “They’ve proven that recycled aggregates can meet industry needs without compromising on quality. It’s inspiring others in our industry to reconsider what’s possible with waste.”

Latest from Construction & Demolition Recycling

- Maverick Environmental Equipment opens Detroit-area location

- Nucor finishes 2025 with 14 percent earnings decline

- G2 Consulting Group acquires Construction Testing Services

- CBI to showcase 5900T horizontal grinder at ConExpo 2026

- Steel Dynamics reports 2025 financial results

- Global steel output continues slide in December 2025

- Smart equipment maintenance: How geofencing drives productivity

- Demo Leaders launches zero-waste program