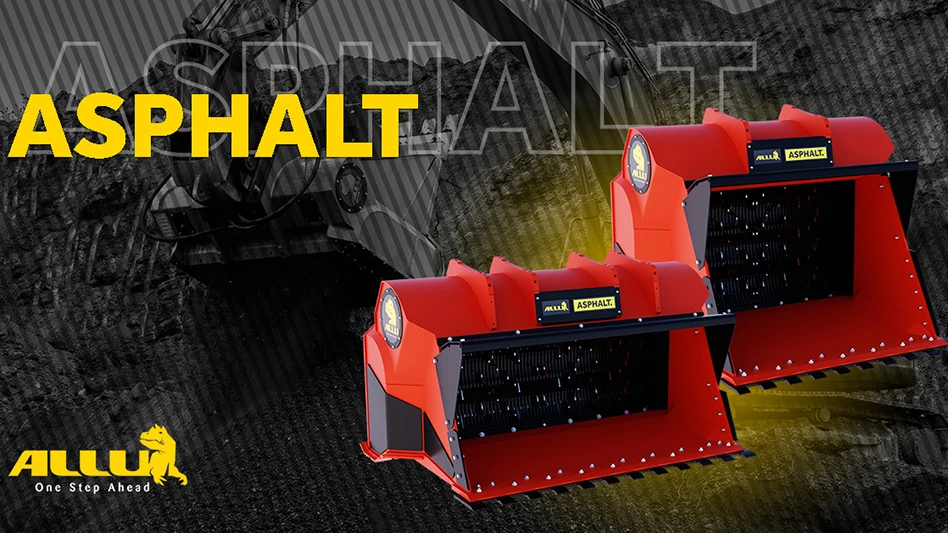

Image courtesy of ALLU

ALLU Finland Oy, a European equipment maker with global operations, says its new line of asphalt screening and crushing bucket attachments can turn milled asphalt pavement material into a high-quality resource on-site, supporting greener, leaner infrastructure development.

The firm describes its ALLU asphalt product line as “a powerful, hybrid screening solution engineered specifically for processing cold-milled asphalt and reclaimed asphalt pavement (RAP) in a faster, cleaner and more cost-effective way.”

“Globally, there’s a clear shift toward sustainable infrastructure in construction business,” says Peter Grönholm, CEO of ALLU. “Asphalt recycling plays a major role in this movement, and our new ALLU Asphalt Bucket empowers contractors to turn reclaimed and cold-milled asphalt into high-quality, reusable material—directly on site. It’s a smarter, more profitable way to work, and we’re proud to help drive this transformation across the industry.”

The firm indicates municipalities, contractors and asphalt producers can benefit from finding “smarter ways to reuse milled asphalt,” and its bucket allows them to process clumps, screen fines and separate oversized particles, all in a single pass.

“At a time when efficiency, sustainability and profitability are key, the ALLU Asphalt Bucket ticks all the boxes,” says Tom Chapman, managing director at MRD Plant, a United Kingdom-based equipment dealership. “It does the job of a mobile impact crusher but at a fraction of the cost and with far less complexity onsite.”

The Asphalt Bucket uses a hybrid blade configuration, or a mix of screening and crushing blades, to “fine-tune performance and achieve consistently high-quality end products.”

“The hybrid blade setup is what makes this bucket so effective,” Grönholm says. “It delivers just the right mix of crushing force and fine screening to process asphalt efficiently in a single step.”

The bucket comes with three screen sizes designed to process more than 95 percent of finished material at below a target size.

Other key features include: one-step operation that crushes and screens simultaneously; lower total costs, thanks to reducing a project’s reliance on mobile impact crushers; and “proven throughput” of up to 250 tons per hour.

The Asphalt Buckets are available in several sizes that can be used in tandem with 25-to-45-ton excavators and 15-to-30-ton wheel loaders.

Latest from Construction & Demolition Recycling

- John Deere announces plans to open 2 new U.S. facilities

- Company incorporates safety, cost of ownership considerations in demo equipment offerings

- Metso adds Florida to Mellot’s distributor territory

- Maverick Environmental Equipment opens Detroit area location

- Nucor finishes 2025 with 14 percent earnings decline

- G2 Consulting Group acquires Construction Testing Services

- CBI to showcase 5900T horizontal grinder at ConExpo 2026

- Steel Dynamics reports 2025 financial results