Recently celebrating its 40th anniversary, Thalle Industries has been a mainstay in New York’s aggregates market since 1985. Based in Briarcliff Manor, New York, the company is the largest recycler in Westchester County, operating three locations that specialize in asphalt, aggregate, concrete and recycled products.

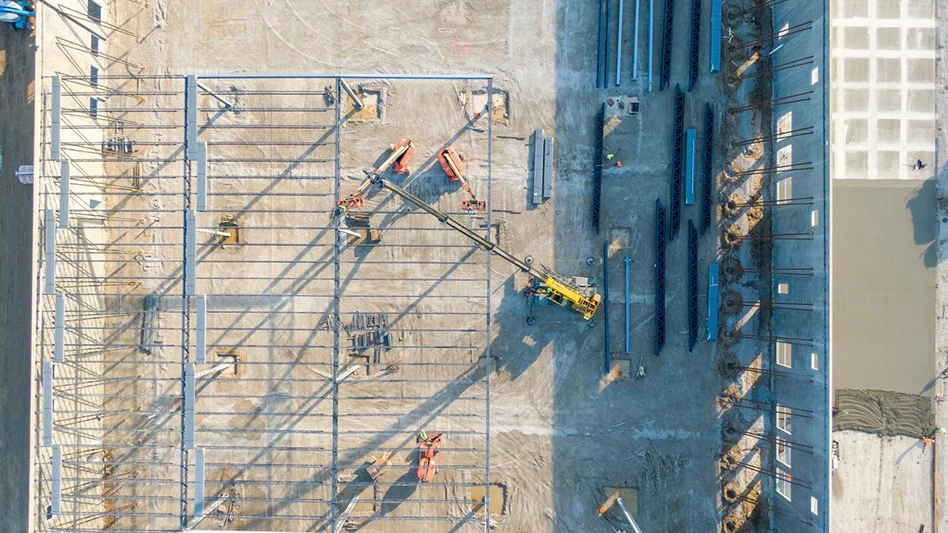

The company originally began as a quarry and asphalt operation at its first site in Fishkill but has since expanded to include a “virtual quarry,” or recycling facility, in Greenburgh and a concrete plant and virtual quarry in Montrose.

“We’re a very environmentally conscious, environmentally supportive material supplier,” Thalle Industries President and CEO Glenn Pacchiana says. “We’re always looking to do more with less. I think the recycling industry is really exciting for us because we’re able to divert a lot of waste that would normally be buried or go into landfills.”

Viewing the recycling industry as a new opportunity to create aggregate products, Pacchiana dubbed the sites virtual quarries because the operations share similarities with traditional extraction methods.

“We drill and blast rock to make our raw ingredients in our virtual quarry,” he explains. “The contractors and municipalities deliver us their waste product, which is our raw material. So, we then take those products, we separate them, we keep everything segregated … and we use those raw materials as a normal quarry would.”

When it comes to processing, Pacchiana says Thalle’s equipment largely mirrors its quarry operations, using a mix of magnets to remove any metals and then feeding the stream to a series of screens and cones crushers. Final specs are achieved with a closed-circuit crushing system, similar to what is used at the company’s Fishkill quarry.

The virtual quarries accept mixed loads of clean, uncontaminated concrete, asphalt pavement and rock, which are processed into mixes ranging from New York Department of Transportation requirements to high-strength specialty batches. Throughout the process, Pacchiana says it’s important to separate materials as quickly as possible and to crush feedstocks individually to ensure a pure end product.

Many of these products are the same spec as what Thalle supplies at its virgin quarry, such as ¾-inch stone and sand.

“We will not just make a blended recycled product,” Pacchiana says. “We make normal products that we would make in our own quarry.”

Inside the operation

The bulk of Thalle’s customers are in the industrial, institutional and municipal sectors, with a small percentage of aggregates being smaller lawn and garden projects.

Although the company is relatively small in comparison to competitors in the New York aggregate recycling space, Pacchiana says this gives Thalle a competitive edge through its ability to offer better service. This is thanks to the company’s Rock Star Service program, which guarantees a response to any inquiry within 24 hours.

Thalle also offers a Rock Star Hero service, which offers customers guaranteed same-day delivery if an order is placed before 10 a.m.

This flexibility extends to the products the company creates, as well, with Thalle providing special blends upon customer request.

“If a customer calls and wants a unique, special blend, we’ll do that for them,” Pacchiana says. “I always say, whatever the customer wants, we will do. If a customer wants us to load at 5:30 a.m., we’ll load them at 5:30 a.m. We have to be flexible, because we don’t have the economies of scale of some of our really big competitors.”

For Pacchiana, the goal is to use everything, so having a constant stream of material flowing in and out of the facilities is paramount. Sometimes, this can prove difficult, as demand can fluctuate yearly.

“One year, you don’t have enough sand, or one year, you have too much sand. Then, one year, you can’t keep enough ¾-inch stone on the ground,” Pacchiana says. “So, it really changes; you have to be nimble.”

Recycling at a virtual quarry is unique, he adds, because the rate of incoming material—a major factor in the balance of Thalle’s supply—is out of the company’s control. However, Thalle’s dense market, diverse product offerings and ability to offer a one-stop solution for customers help to ease these challenges.

“We have a pretty wide market,” Pacchiana says of Thalle’s service area. “We cover anywhere from New York City up to Poughkeepsie, really, anywhere along the Hudson Valley.”

Adding value

Despite being in the virgin quarry business, Pacchiana says he prioritizes the use of recycled aggregates as much as possible and continuously is fighting to change the narrative surrounding second-life materials.

“There’s a perception that recycled materials are bad,” he says. “I would challenge those people to come visit our facilities because we’re different than a typical recycling facility. We are a virtual quarry, so we are making recycled materials, but we’re doing the same thing we do in Fishkill at our virgin quarry.”

To further challenge preexisting ideas regarding recycled aggregate, Pacchiana says the facilities are open to anyone curious—a tactic that has helped Thalle secure jobs, such as a supply agreement with the New York City Department of Environmental Protection.

“I think every place has a little bit of a not-in-my-backyard issue, and I think it’s up to the recycling and mining community to be good neighbors and show people that … [they] want us in their community,” Pacchiana says.

Being present in the community also is important, Pacchiana adds, and Thalle’s concrete trucks are frequently painted with the logos of local organizations such as the Westchester Parks Foundation and animal shelters.

“It’s really important to the local community to be supportive and [to be] leaders, and I think that’s one thing that we’ve done really well,” Pacchiana says.

Explore the July/August 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Nucor finishes 2025 with 14 percent earnings decline

- G2 Consulting Group acquires Construction Testing Services

- CBI to showcase 5900T horizontal grinder at ConExpo 2026

- Steel Dynamics reports 2025 financial results

- Global steel output continues slide in December 2025

- Smart equipment maintenance: How geofencing drives productivity

- Demo Leaders launches zero-waste program

- BrightRidge to demolish 2 buildings in Tennessee