Omega III LLC thrives on projects with tight schedules and high safety requirements. Those challenges bring opportunities, which in turn have allowed the Elgin, Illinois-based demolition company to shine.

“We maintain strong, honest relationships with clients and our crews,” Omega III General Manager Chuck Gerage says. “We build trust through consistent performance and problem-solving. We protect our employees—safety is a very big driving factor in all our decisions. And we deliver, which brings back clients.”

Carving its niche

Operating predominantly in the Midwest, Omega III has carved out a niche in the bridge and heavy civil demolition markets but also has worked on industrial plants, commercial buildings, interior strip outs, structural and selective demolition projects.

The company was founded in 1997 by Chuck and Jim Gerage with a simple model to deliver high-quality demolition work and a reliable crew. The company initially focused on interior demolition and smaller selective tear-outs throughout the Chicago area.

As Omega III developed a reputation for taking on and executing difficult work, its opportunities grew. By the mid-2000s, the company expanded into structural demolition, industrial teardown and mass concrete removal. It became known for tackling projects that required speed, engineering coordination and high-stakes safety performance.

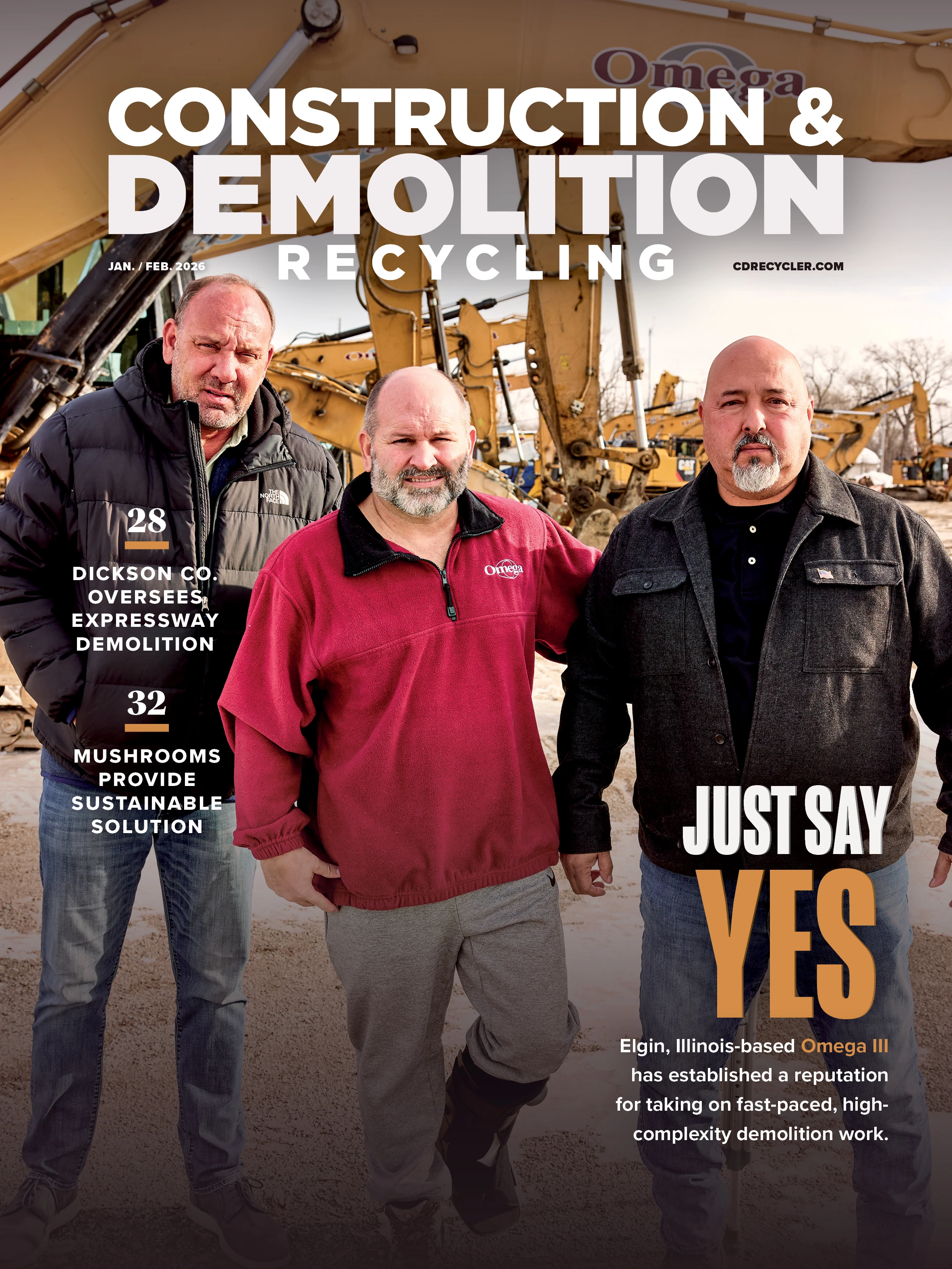

But the sudden death of Jim Gerage in 2016 caused the company to restructure and relaunch in 2018. Mike McMahon, vice president of estimating, and Daniel Dela Rosa, vice president of operations, became co-owners along with Chuck Gerage.

McMahon worked in the steel industry until the late 1990s, when he met Gerage, and has since taken on increasing roles with the firm. Dela Rosa has been with Omega III for 27 years, starting as a foreman in its environmental group.

“That was a tough time,” Dela Rosa says of the late 2010s. “We lost Jimmy, who was a major component of running our full operation. And those changes were really challenging in the beginning. We were really starting a fresh company, getting funding and marketing ourselves anew. It changed everything. But we also had a lot of support behind us from our customers that knew us and built relationships with us. They knew the way we did things and how sound the company’s values are.”

Today, Omega III takes on fast-paced jobs across the Midwest and has earned a reputation for completing high-risk projects safely, efficiently and correctly. It’s also built out its management and estimating teams over the years and, in turn, has increased its geographic footprint.

Omega III also has invested in its operations, including purchasing larger equipment, different attachments and other technologies. The firm uses high-reach excavators, hydraulic shears, grapples, pulverizers, breakers, hammers, saw cutting equipment, torches, specialty demo tools and heavy trucks to process and move materials.

It also leans on other advanced demolition attachments and tooling to perform self-fabricating on some of its more complex projects and deploys drones for planning and surveying.

“We perform schedules ahead of time to lay it out, so we deliver on time,” McMahon says. “With our more complex jobs, we also have detailed engineering that we follow. Our plans are typically staffed by third-party engineers, and we have everything laid out for our field crews, so they have a playbook [on] … how to perform the work and how to get it delivered on time, within budget and safely.”

Plan for success

Every site brings unique obstacles, but Gerage says safety is at the heart of every decision. The company follows Occupational Safety and Health Administration (OSHA) and Environmental Protection Agency requirements.

“First, we believe in OSHA’s leadership,” he says. “We follow the OSHA standard, which is the minimum, so we always try to do better than the OSHA standard. We have daily job hazard analysis done and weekly toolbox talks. We have strict personal protective equipment [PPE] and equipment protocols. We control traffic and pedestrian barriers and communicate with all people involved. We put safety first.”

Dela Rosa has extensive training and experience in managing safety and environmental hazards, holding a license as a lead and asbestos supervisor. The firm performs asbestos surveys on every structure prior to arrival on-site and pulls samples from painted surfaces so it knows what to expect.

McMahon says for industrial sites, Omega III engages the owners to get an idea of the various chemicals that might be left in the pipes if they were purged.

“We conduct detailed site and structural reviews,” Gerage says. “We identify hazards and utilities beforehand. Then, we’ll develop a custom demo plan and [the] sequence that will come with that. We have daily meetings on the job, so there’s constant communication with the general contractors or agencies to adapt the plan as conditions evolve.”

Omega III walks each site to develop a demolition plan with a focus on recycling. On most projects, the company says it recovers 90-98 percent of materials, including concrete, brick, metals, asphalt and select architectural fixtures. Its program includes:

- concrete and brick crushing, reusing the resulting material as backfill or engineered fill;

- steel separation and shipment to regional mills;

- nonferrous metal sorting on-site or at recycling partners;

- asphalt recycling for road base and hot-mix production;

- wood and pallet recovery when applicable; and

- lead and hazardous metal segregation in compliance with environmental regulations.

“It just depends on what type of building or structure, if the material will get crushed and what’s inside of the building. But we try to recycle everything we can on every project,” McMahon says.

Rapid response philosophy

The company’s shift toward fast-paced, high-complexity demolition work accelerated during the past two decades as ownership recognized a need for a subcontractor that could mobilize quickly, think creatively and execute work safely under compressed schedules. This led to an increase in public-sector, transportation and industrial shutdown work for Omega III.

At the heart of this success is the company’s rapid response philosophy, starting with a fleet and workforce that can move on short notice and a willingness to say yes to difficult timelines.

Gerage says field leadership often makes decisions in real-time to solve problems as they arise without waiting for multiple layers of approvals.

“We have a lot of long-term employees who have been around, just like me, for decades,” Dela Rosa says. “These guys are top-notch in the field. Our operators, our labor crews [and] our foreman have all been around for a long time, which is not ordinary for this kind of business. I think a lot of that has to do with the challenging work that we can pursue and the way these guys are taken care of and treated fairly. Guys want to come to work and know that we’re not going to cut corners. We’re going to do the right thing. We’re going to do it [safely].”

An example of this occurred in 2021 when Omega III completed the demolition and debris disposal of 46 separate overpasses as part of the I-65 and I-70 North Split project for Superior Construction, based in Portage, Indiana; and the Indiana Department of Transportation. Located in downtown Indianapolis, the firm demolished parapets, crash walls, decks, beams, abutments and piers.

During precutting inspections and air-monitoring protocols, the firm discovered lead paint within one of the top flanges of the steel beams. Omega III immediately notified Superior Construction, and the two worked together to isolate the contaminated components, activating its hazardous material protocol.

The firm says the isolation plan was formed within hours. Omega III and Superior Construction worked together to install temporary containment barriers, implement negative air systems where needed and use special PPE and cutting tools rated for hazardous material handling.

The companies also developed a removal and disposal plan in compliance with state and federal requirements, documented all steps and maintained air monitoring throughout the project.

“It takes eyes on the job to understand something that small on the underside of a concrete bridge deck,” Dela Rosa says. “A lot of people would overlook that, and that could have been a bigger problem. They were very happy that we caught that.”

Everything comes together

The Illinois Department of Transportation (IDOT) named Omega III the 2024 Outstanding Subcontractor of the Year for its work in demolishing the three-unit, eight-span concrete structure with supporting columns integral to the bridge over I-94/I-90 at the Ohio Street Interchange in Cook County, Illinois.

“It was a proud moment for us,” Dela Rosa says. “Everybody had a hand in it. From the guys who planned in the office, our engineering team and down to the guys in the field. The dedication and hard work that was put into that says a lot about how hard our guys are willing to work.”

McMahon says live utilities had to remain open during the project. The ramp itself was an interchange section on I-94, meaning traffic was entering and exiting the highway. Omega III had to protect the live utilities while working in a tight time frame to avoid disrupting the daily flow of traffic.

“It was located in a highly congested urban environment, so the work had to be done on nights and over the weekend due to traffic constraints,” Gerage says. “Heavy coordination and major planning were needed. There was just a very tight work area that had major safety requirements. There was really no margin for error. We did custom engineering. We had immediate mobilization and [an] accelerated time [line] we coordinated with IDOT and the police [and] utility companies. We had our special equipment out there to tackle it. We had our specialized equipment with attachments. We executed on time without any incidents.”

Omega III used a rapid mobilization plan to accelerate work windows. McMahon says backup equipment was on-site so that if one piece of machinery needed maintenance, another could slide in and take its place because the firm could not afford to lose time servicing equipment.

McMahon adds that Omega III had to systematically demolish the structure based on where it could fit the equipment. The firm used specialty equipment and larger hammers, which he says is one reason why it was able to get through the concrete more quickly.

As the bridge started coming down faster than anticipated, McMahon says Omega III called a meeting with IDOT on-site and greenlit the demolition of the second unit earlier than expected. The firm ultimately completed two of the units in one weekend.

“Our success came from pure planning,” McMahon says. “Everything was done on an hour-by-hour schedule. The whole project was supposed to be three separate weekends where we were taking out units. We got it done in two, saving one whole weekend. The process we had allowed us to get the second unit done in one of the weekends where we were only supposed to do one of the units.”

Explore the January/February 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Vecoplan appoints CFO

- CDRA Conference & Tradeshow 2026: Creating a market for gypsum recycling

- John Deere announces plans to open 2 new U.S. facilities

- Company incorporates safety, cost of ownership considerations in demo equipment offerings

- Metso adds Florida to Mellot’s distributor territory

- Maverick Environmental Equipment opens Detroit area location

- Nucor finishes 2025 with 14 percent earnings decline

- G2 Consulting Group acquires Construction Testing Services