Mitchell Stephens, the owner of Atlanta-based Metro Green Recycling, has been involved in the construction industry since he was 13 years old. Born and raised in Snellville, Georgia, he participated in pipeline, road and heavy civil projects from Virginia to Texas, gaining firsthand experience in innovation and problem solving.

With much of the construction and demolition (C&D) waste stream traditionally destined for landfill, Stephens identified the need for reliable, alternative disposal methods. Convinced that current residential and commercial trends in Atlanta would continue to create high demand for C&D disposal options, he felt compelled to explore the possibilities of the recycling space.

After earning a civil engineering degree from Southern College of Technology (now Kennesaw State University) in 1993, Stephens started looking into the viability of starting his own recycling operation, Metro Green Recycling.

With no prior experience in C&D recycling, he began researching the industry’s possibilities, traveling to several locations across the country in search of methods and systems best suited for the Atlanta market.

New beginnings

In 2010, the company acquired the property for its first facility, known as Metro Green Recycling One. Located in Gwinnett County, the property previously was home to a cardboard manufacturing plant. To create the C&D recycling facility, Metro Green demolished two-thirds of the 210,000-square-foot structure, constructing a C&D sorting and processing operation in the remaining 70,000 square feet and a concrete recycling system on a remaining concrete slab.

After undergoing the necessary zoning and permitting, the facility opened in January 2012, focusing on concrete, wood, metal and cardboard recycling.

The facility is now a full-service C&D recycling facility, accepting mixed C&D material, including the aforementioned materials as well as plastics, carpet, drywall, brick, roofing shingles, acoustic ceiling tile, shot rock and more. These are sold into various end markets, with Smurfit WestRock purchasing Metro Green’s sorted cardboard and Radius Recycling purchasing scrap metal.

In 2014, Metro Green expanded with a second location in northwest Atlanta, Metro Green Recycling Two, dedicated to recycling concrete into construction-grade materials.

This site also was home to a former cardboard manufacturing plant, but the process of developing it was much simpler because concrete recycling doesn’t necessitate additional permitting. The site also required no demolition work and only the removal of a mobile office, so once equipment was placed on the property’s existing concrete slab, operations were up and running.

In 2020, Metro Green Recycling acquired a 275-acre landfill, of which 90 acres were permitted, for sale in Franklin County, Georgia, which accepts concrete, wood, cardboard, drywall, carpet, asphalt shingles, brick and metal.

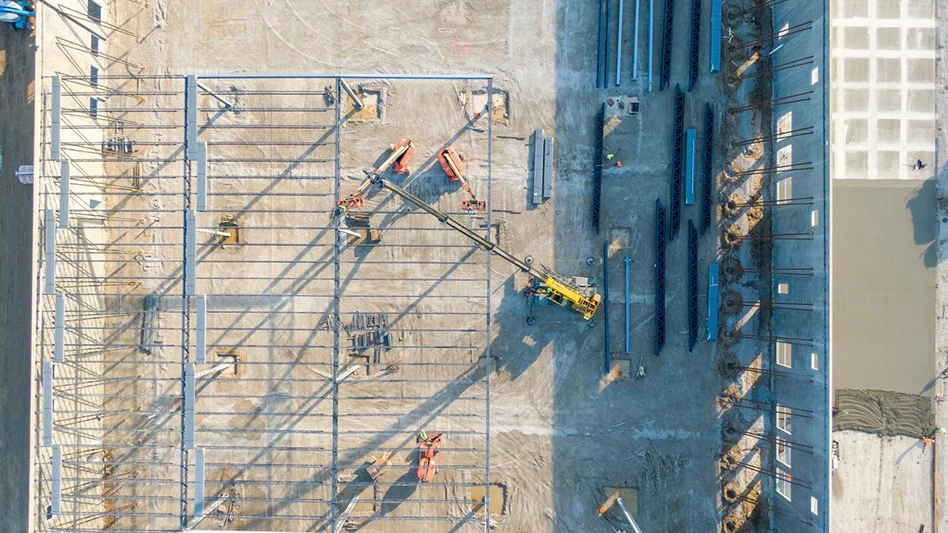

More recently, the company has begun developing a third facility, called Metro Green Recycling Three, on the east side of Atlanta. With an anticipated opening in the near future, Stephens says the facility will be a full-service C&D material recovery facility with a concrete plant similar to the original location.

“This new facility will serve as Metro Green’s second full-service C&D recycling operation, bringing new jobs and economic opportunities to the Stonecrest, [Georgia], community,” Stephens says.

Across its facilities, which range from 10 to 35 acres, Metro Green manages more than a million tons of C&D material per year. The company produces several recycled concrete aggregates, including Georgia Department of Transportation-approved Graded Aggregate Base and No. 57, No. 34 and surge-sized aggregate, which are sold to contractors for various applications in the Atlanta construction market.

Metro Green also produces biofuel from C&D wood, which is used to produce electricity at a nearby power plant. For this operation, C&D wood, lumber and pallets are run through a grinder and brought to a wood shed via conveyor. From here, the material is loaded and hauled to the power plant, just east of Atlanta.

To manage these materials, the company uses a suite of mobile and stationary equipment. Mobile equipment includes primary wheel loaders, excavators, skid steers, water trucks, bulldozers and compactors, most of which are supplied by either Komatsu or Caterpillar.

For concrete recycling, Metro Green’s facilities are equipped with machinery from Superior Industries; Lippmann; KPI-JCI, a member of the Astec Industries family; Dings Magnetics and Deister. In the C&D recycling facilities, a mix of West Salem Machinery, Action Vibratory Equipment, Sparta, Master-Mag and Rotobec equipment is used.

About a year and a half ago, Stephens says, the Metro Green Recycling One facility underwent a substantial upgrade with Canada-based Sparta, adding Dense-Out air separator chambers, constructing 13 conveyors and reconfiguring the layout to optimize material diversion.

Navigating the market

A majority of Metro Green’s business comes from commercial construction companies with a significant need for materials disposal or recycled aggregate products. The rest comes from residential customers performing projects around Atlanta, ranging from subcontractors and nearby residents to one-time customers with a need for local C&D management, Stephens says.

Metro Green General Manager Mark Black says the Atlanta metro area has one of the largest and most active C&D markets in the southeastern U.S., largely driven by rapid urban growth, infrastructure expansion and real estate development.

With ongoing growth in the residential, commercial and transportation sectors, the volume of C&D debris generated in the region continues to rise.

Despite this growing volume, Black says a key challenge still facing the industry is misconceptions surrounding C&D recycling operations.

“The materials that we handle are the same materials that surround people in their homes and neighborhoods. C&D recycling is actually very environmentally beneficial, not harmful,” he says.

Black, who has worked in the construction industry since earning his bachelor’s degree in civil engineering from the Georgia Institute of Technology in 1983, has been with Metro Green since 2010.

“Many Americans are unaware of the importance and benefits of recycling C&D materials,” he says.

According to the Environmental Protection Agency, C&D debris accounts for approximately 40 percent of the total waste generated in the U.S. each year; however, Black estimates that fewer than 15 percent of recycling facilities nationwide are dedicated exclusively to processing C&D materials.

“Many communities may not realize how recycling helps reduce pressure on local landfills and helps support long-term sustainable waste management solutions,” he adds.

On a broader scale, Black says inconsistencies in recycling policies across different municipalities can contribute to the problem.

While some local governments have strong recycling programs, he says, others have minimal or unclear requirements, making it challenging for recycling facilities and businesses to operate. In Georgia, specifically, Black says the state lacks comprehensive, statewide mandates for C&D recycling, which can “limit both diversion rates and the broader economic and environmental benefits that recycling provides.”

“Expanding and streamlining local and state recycling policies would not only aid in the diversion of materials from overburdened landfills but also create jobs, support economic development and contribute to long-term sustainability in Georgia communities,” he says.

While these gaps can cause inconsistency across the market, Black says federal initiatives like the Leadership in Energy and Environmental Design, or LEED, program, a framework for assessing the sustainability of building projects offered by the U.S. Green Building Council, have helped promote recycling efforts.

Building a strong base

Both Stephens and Black credit much of Metro Green’s success to its ability to adapt and overcome.

“It’s been a constant learning curve to develop more efficient ways of recycling,” Stephens says. “Every year, we have some type of capital improvement to increase productivity, efficiency or safety. We always look at something and try to figure out a better way.”

When it comes to the company’s business philosophy, Metro Green’s top concern is providing quality products and services for its customers.

“With our customers, we have to do what we say we are going to do,” Black says. “We have to deliver a quality product at a fair market value. If we have a problem, we fix it.”

This belief system extends to the company’s roughly 100 employees, who Stephens and Black describe as the backbone of Metro Green Recycling. For them, it’s all about the people, and a company cannot have great success without a good team.

“You can’t build a great business without a strong, dedicated team,” Black says. “In any industry, success depends on both earning the trust of your customers and investing in your employees.”

As the company continues to grow, refining operations to improve efficiency and increasing recycling rates are top of mind for its owners. Over the past year, Metro Green has set the stage for an increased presence in Atlanta through its expansion and redesign of Metro Green Recycling One and the development of its new facility, Metro Green Recycling Three.

“We’re always looking to expand,” Stephens says. “Greenfield sites can be a challenge due to NIMBYism, [and] acquisition of land and entitlements takes a lot of time, money and politics.”

Because of these challenges, Stephens says any future expansions will likely come from acquisitions in adjacent markets and other types of businesses.

Explore the July/August 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Maverick Environmental Equipment opens Detroit-area location

- Nucor finishes 2025 with 14 percent earnings decline

- G2 Consulting Group acquires Construction Testing Services

- CBI to showcase 5900T horizontal grinder at ConExpo 2026

- Steel Dynamics reports 2025 financial results

- Global steel output continues slide in December 2025

- Smart equipment maintenance: How geofencing drives productivity

- Demo Leaders launches zero-waste program