Yanmar initiative focuses on electric power

Japanese manufacturing company Yanmar Holdings Co. Ltd., which has U.S. operations based in Grand Rapids, Minnesota, has launched an organization dedicated to advancing electrification in its line of compact off-highway equipment.

Yanmar’s Electrification Unit started operations in April and focuses on delivering a “diverse portfolio” of e-powertrain solutions, including batteries and electric drives.

“The development of [electric] powertrains is crucial for adapting the expertise we have built with diesel engines to a broader range of applications beyond just construction and agricultural machinery, and it represents an important step towards achieving carbon neutrality,” says Tetsuya Yamamoto, chief operating officer of Yanmar Holdings.

Yanmar says the business unit will work closely with long-standing customers to electrify applications such as excavators and wheel loaders.

In recent years, the company has invested in research and development in low-emission technologies, citing its 2022 acquisition of Netherlands-based battery development company Eleo Technologies.

The Electrification Unit operates on a global scale, with Yanmar saying the business unit draws upon an international network of teams and resources so it has worldwide reach while tapping into localized expertise.

The unit’s establishment aligns with Yanmar’s broader Green Challenge 2050 initiative, the company says, reinforcing its commitment to a sustainable future tied to electrification, alternative noncarbon fuels and resource recycling solutions.

Yanmar has appointed industry veteran Marko Dekena to lead the Electrification Unit.

Viably, Turmec partner on Ohio installation

Equipment and technology providers Viably LLC and Turmec say they are working in partnership to assist Boyas Recycling, Valley View, Ohio, to develop and install a mixed construction and demolition (C&D) materials sorting plant. Viably, based in Denver, and Ireland-based Turmec announced in March their alliance to work together on North American systems installations.

The companies call the installation of the planned C&D material recovery facility (MRF) in the Cleveland area a process that “marks the launch of an innovative waste management plant system integration that leverages the combined expertise of Viably and Turmec.”

The project represents a step forward for Boyas Recycling in its quest to evolve into a fully vertically integrated company, the companies say.

“With core operations spanning front-load service, container service, an active C&D landfill, mulch production and soil and aggregate operations, this groundbreaking facility is key to its continued growth and sustainability efforts,” Viably says of Boyas.

The company adds that the MRF has been designed to process more than 150,000 tons of C&D materials annually. The facility, scheduled to go online in the second half of this year, will operate with an initial targeted recovery rate of at least 80 percent, according to Viably.

The new facility will include advanced process flow with heavily automated optical sorting and mechanical treatment technology; a compact footprint incorporating shredding, primary and secondary screening, ferrous and nonferrous separation, ballistic separation and optical sorting in one cohesive system; with minimal labor, requiring only eight manual sorters.

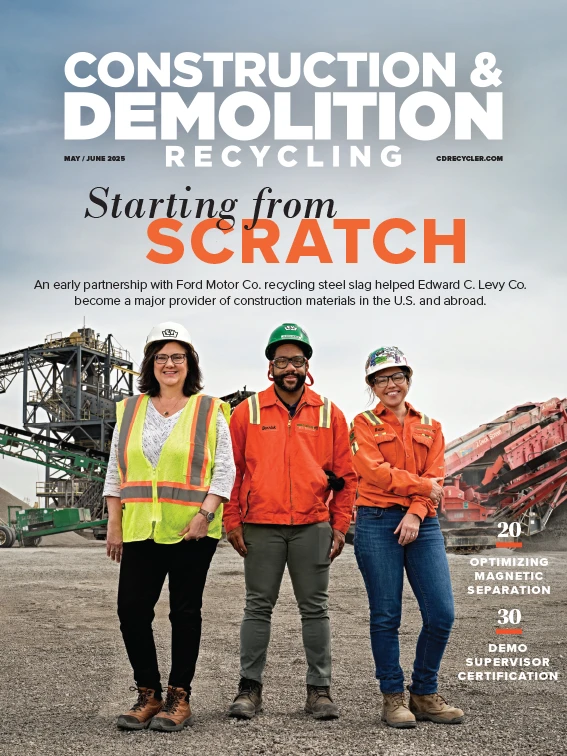

Explore the May/June 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Metso adds Florida to Mellot’s distributor territory

- Maverick Environmental Equipment opens Detroit area location

- Nucor finishes 2025 with 14 percent earnings decline

- G2 Consulting Group acquires Construction Testing Services

- CBI to showcase 5900T horizontal grinder at ConExpo 2026

- Steel Dynamics reports 2025 financial results

- Global steel output continues slide in December 2025

- Smart equipment maintenance: How geofencing drives productivity