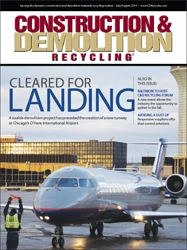

The History Channel television show “Life After People” has as its premise what would happen to buildings and other man-made structures if humans suddenly disappeared. On a late autumn afternoon in 2009 the neighborhoods in the northeast corner of Bensenville, Ill., adjacent to Chicago’s O’Hare International Airport, looked like a real life set for the show. Airport expansion in the form of new Runway 10 Center (10C) was the reason for the “ghost town” appearance taken on by the neighborhood.

Most of the buildings and homes had been vacant for several years while litigation involving when the demolition process could begin was ironed out. One of the major points of litigation involved the logistics of relocating a 161-year-old 6.3-acre cemetery with at least 900 known graves. The issue was a sensitive subject and the City of Chicago worked diligently to contact next of kin of those buried in the cemetery while attempting to demonstrate care and compassion while working out relocation processes.

Much of the new runway has now been built, with the completion on hold until the cemetery issue is resolved.

NATURE’S HEAD START

During the years of abandonment, the ravages of the harsh northern Illinois climate had taken its toll on many of the un-maintained residences and commercial buildings.

Vegetation was beginning to take over most of the yards and other properties. A herd of whitetail deer was feasting on the remains of lawns and ornamental shrubbery. Other wildlife, including coyotes, roamed freely around the abandoned areas. As nature was steadily reclaiming these neighborhoods, off in the distance could be heard the almost constant roar of passenger and cargo aircraft taking off and landing. It was an eerie contrast that the abandoned neighborhoods were quiet on the ground while the very active neighbor “next door” was about to increase the size of its property.

The Chicago Department of Aviation (CDA), through the City of Chicago, acquired by eminent domain about 400 acres of land consisting of more than 500 residential and commercial buildings for the purpose of implementing the approximately $15 billion O’Hare Modernization Program (OMP).

The OMP has been designed to update and expand the runway configuration of the country’s second busiest airport, which handled 64 million passengers in 2009. An additional terminal may also be built on the western edge of the airport.

The abandoned area of Bensenville in the OMP land acquisition area is located primarily in the footprint of a new north/south runway in the proposed project. The goal is to complete the new runways by 2014, which ideally will decrease airport delays and expand capacity.

The OMP is believed to be the largest airport reconstruction project in United States history. The entire project is estimated to be creating 13,000 jobs over its timeline. About 113 of these jobs are directly related to the demolition work.

A press conference was held in the middle of new Runway 10C on March 24, 2010. Piles of concrete chunks from old runways and taxiways were piled nearby waiting to be crushed and pulverized and recycled for use in the new construction. CDA Commissioner Rosemarie S. Andolino stated, “The successful agreement we reached with the Village of Bensenville and the demolition work that starts today represent major milestones as we move forward with construction on the OMP.”

Village of Bensenville President Frank Soto accompanied Andolino at the news conference. Soto said, “I want to thank the City of Chicago and Commissioner Andolino for working closely with the Village of Bensenville to employ and develop the most stringent demolition protocols that exceed the minimum state and federal standards.”

Once an agreement was obtained with the Village of Bensenville and other parties, there was a period of time before actual demolition was to begin. During that time, abandoned commercial and residential areas offered an opportunity for emergency responders such as the U.S. Dept. of Justice’s Alcohol, Tobacco and Firearms agency and local fire and police departments to use the structures for training purposes.

GETTING TO WORK

The official demolition process began on the afternoon of March 24, 2010, with a commercial building that formally housed a construction company, a coin-operated laundry, hot dog stand-type restaurant and a graphic arts business.

Two tracked excavating machines equipped with pulverizing shear attachments tore into the structure while ground-based workers trained a steady stream of water from hoses to keep dust and particulates under control. Air quality including particulates is being monitored through the entire demolition process which, except for one final contract, has a target date of being completed by September of 2010.

As of late May companies that have been involved contractually with the OMP in regard to demolition and recycling of materials include:

• DMD Services Inc., Lake Forest, Ill.;

• Brandenburg Industrial Service Co., Chicago;

• McDonagh Demolition Inc., Chicago; and

• American Demolition Corp., Elgin, Ill.

Additionally, remediation companies have been contracted to properly dispose of any materials that are not appropriate for standard landfills or recycling. For example, all fluorescent light bulbs, fixtures and ballasts are being removed. Only after a report for a particular building is completed to assure removal of all hazardous materials can demolition take place.

As of the 2010 Memorial Day weekend, about 65 percent of the demolition had taken place in the Bensenville residential and commercial areas. Thus far, it is estimated that more than 90 percent of the materials generated will be recycled.

One of the key components for all projects implemented by the CDA and with the OMP is sustainability. All demolition is being done in accordance with the CDA Sustainable Airport Manual (SAM). This manual integrates airport-specific sustainable planning and practices from the design phase through construction, operations, maintenance, and other functions. (More information on SAM is available at www.airportsgoinggreen.org.)

| GETTING TO KNOW SAM |

|

All demolition at the Bensenville site is supposed to take place in accordance with ordinances required by the City of Chicago, the SAM (Sustainable Airport Manual crafted by the Chicago Department of Aviation) and supporting “Specifications for Construction Waste Management and Construction Equipment.” |

EMPHASIZING RECYCLING

Before and during demolition, an evaluation of potential for reuse of all products and materials such as concrete, bricks, metal, and wood was performed.

Contractors are making all possible efforts to recycle all steel, copper, and aluminum. Stone, gravel, rocks, masonry, concrete wall panels, and concrete and asphalt also are being crushed and recycled.

Construction material such as plaster and gypsum drywall are being recycled when possible, as are plumbing fixtures. Carpet and padding, non-asbestos insulation, roofing shingles and materials are also being evaluated.

All recyclable cardboard, paper, packaging, plastics, glass and landscape debris is being processed. Mixed demolition debris is being moved to sorting facilities that are in close proximity to the demolition site.

There are also significant amounts of materials that have or will be salvaged for re-use by demolition contractors and the City of Chicago. Included in that category are door frames and hardware, windows and frames, face brick, parking bumpers, loading dock levelers, electrical circuit breaker panels, switches and equipment, mechanical heating and air conditioning equipment, lights and light poles, public utility equipment such as hydrants, manhole covers and pumps, and other materials left on the project site by former tenants and residents.

So far, 67 trees and shrubs also have been salvaged and replanted for landscaping projects around O’Hare.

Some building components require an extra effort to recycle, such as insulated concrete wall panels. The insulation and reinforcing must be separated from the concrete. Steel roof decking is cut into smaller pieces on site. Wood framing from houses to be recycled involves separation of non-wood materials such as shingles and drywall. Much of the residential material has been taken to the nearby mixed C&D sorting facilities.

THE SAME PAGE

The CDA is the official developer of the OMP project and is working with the contractors involved to ensure recycling and the “green” aspects are being carried out. One of the contractual obligations is recycling is to be done in compliance with the City of Chicago Construction and Demolition Debris Recycling Ordinance. (This also is a requirement of the SAM.)

The project is subject to Chicago’s waste ordinance (Chicago Code Section 11-4-1905) that requires contractors to recover at least 50 percent by weight of demolition debris. The SAM requirements and rating process is implemented through OMP specifications (Construction Waste Management Section 01524). This states that the project meets Chicago Ordinance requirements but also encourages surpassing the minimum of 50 percent recycling of demolition debris as measured by weight. The OMP-SAM gives extra points and encouragement for 75 percent recycling of demolition waste and another tier of points for 90 percent recycling of demolition waste.

Demolition sustainability requirements are identified immediately during pre-bidding of contracts and continue through the demolition process.

Regarding the timetable, the goal is to have 95 percent of demolition completed by September 2010 with a final demolition contract that starts in August to be completed by the end of 2010.

Recycling some 90 percent of the material generated from such a large project–roughly 20 city blocks–is an encouraging testament to how the economics of recycling and “green” initiatives are combining to bolster the C&D recycling industry.

Explore the July 2010 Issue

Check out more from this issue and find your next story to read.