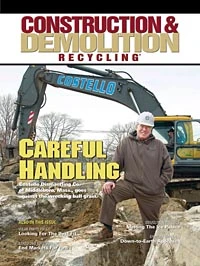

Dan Costello, president of Costello Dismantling Co., wanted a logo that would represent the way his company worked. The Middleboro, Mass.,-based company used the word dismantling in its name for a reason—it rarely used a wrecking ball and tried to salvage as much material as it could with each job.

After much research, Costello discovered that the praying mantis, which carefully dissects its prey before eating it, would be the perfect symbol for his demolition company. So now the image of the stick-figure-like insect adorns everything including the company letterhead and promotional brochure, the outside of the office building and the weathervane on top of Costello’s house.

"What we did was not symbolized by the wrecking ball," says Costello. "We consider ourselves dismantlers. The landscape in New England is very congested, and we are always working in tight quarters. Our projects demand precision and finesse."

RECYCLING APPROACHES

Rather than using a wrecking ball, Costello Dismantling relies almost exclusively on excavators with attachments to handle its jobs. It also relies on careful pre-planning of its jobs in order to recover as much material as possible, says Costello.

The company does not have a landfill, and tipping fees in New England are easily $60 to $80 per ton, depending on the location. "Through salvage and recycling techniques we remove millions of tons of material from the waste stream every year. This allows us to keep our costs competitive," he says.

The trick is to watch the transportation costs closely and not commingle materials: "Keep the wood out of the concrete—stuff like that," Costello says.

That kind of thinking should help when Costello opens its planned recycling industrial park on a 25-acre site that will also serve as the company’s headquarters and maintenance facility. The yard will recycle metals and concrete at first, with later plans including a sawmill and other machinery to handle architectural woodwork, he says. "There is a strong market for that wood. Most of it is yellow pine that is used for flooring and cabinetwork."

Of course, the company salvages more than wood, especially from its many industrial and commercial customers. There are metals and aggregates, with the latter sometimes processed by the company’s own crusher. Compressors, generators and processing equipment of all types are recovered and resold. "We see the buildings of a wide variety of industries, and it is interesting how so many of them use the same type of equipment," Costello says. "It helps that we have contacts in many industries and can cross-sell over those boundaries."

STAYING BUSY

About eight to 10 jobs are going on at any one time under the Costello name, with the range of those jobs being anywhere from $50,000 to $10 million. Costello believes that his company needs to be active in several industry sectors to minimize exposure to market fluctuations in one area, so Costello Dismantling serves all segments.

| Army Surplus |

|

Costello Dismantling was the contractor that worked with the University of Florida on a deconstruction pilot project at Fort McLellan in Alabama. Three old barracks were taken apart using three different methods to test the economic feasibility of each technique and whether doing deconstruction on those types of buildings was worth the expense. The three methods used were: • Stick by stick, or taking each piece apart as far as possible to get as many individual pieces as could be gained; • Small panels, averaging a few feet by a few feet, were pulled off the building with the help of laborers and mechanical equipment; • Large, modular panels, such as half the roof, were set aside at one time. All three had similar recovery rates, but Dan Costello says the latter method was the most cost-efficient for a few reasons. "We put the big panels on the ground and it was easier to work with them," says Costello. "That method fit better into our overall capabilities." Also, overall was the fact that deconstruction, even using mechanical equipment ,such as a crane and excavators, for as many tasks as possible, was slower than traditional demolition. |

However, it is strongest in the commercial and industrial segments and has done several refinery sites in the oil and chemical industries. "We can now bring down a 54-foot-high oil tank in one day, with one worker and one excavator," he says. He adds that is a long way from 30 years ago when he started in the business. "In the old days, we might have 10 or 12 guys up in the air with torches to take something like that down," he says. "Now it is one operator with full hydraulic capabilities. That saves on costs and improves on safety."

Indeed, at the risk of jinxing them, it must be mentioned that Costello has a current record of no lost time accidents over more than 600,000 hours. "You just can’t take it for granted," he says. "We work to minimize the dangers associated with modern demolition techniques."

Even with that record, Costello reports that like all demolition contractors, he has seen an increase in insurance rates since Sept. 11, 2001. "Before then we had seen a decrease in rates," he says. "Our industry needs to get recognized for safety improvements and liability reduction."

Costello Dismantling relies on 14 excavators to execute its projects. There are two large Komatsu PC1000s, five Komatsu PC400s, six Volvo EC460s and a Komatsu PC450 with high reach capabilities. The 85-foot-high boom on the latter unit has been a tremendous help to the company, Costello says.

"The extra-long boom gives us more precise control when taking down a building," he says. "It is great for a four- to six-story building in tight confines. It allows us to precisely remove partitions and control how a wall will fall and allows us to pick timber from five-story buildings without damaging them."

For attachments Costello uses Nye and LaBounty pulverizers, LaBounty shears and grapples and Genesis shears, grapples, and its Demo Pro tool. "We spent a lot of money early on to equip our excavators with full hydraulic capabilities for rotation of shears, pulverizers, etc.," he says. "In addition, we have the hydraulics designed for easy interchangeability between the excavators. By doing this we are able to do most of our work mechanically."

Costello claims an 85 percent to 95 percent recycling and reuse rate on material generated through its work, with that rate jumping to 100 percent on the big steel tanks. He credits the high recycling rate to facilities operated by the many C&D recyclers in the New England area where the company can send its material.

This adherence to environmentalism, which just makes economic sense, he says, is a fact for which the demolition industry is not recognized. "It has always been fashionable to recycle and reclaim in the demolition industry." Costello says, "It is important that we do get recognized. We have a responsibility to owners to handle and dispose of the material properly and responsibly."

The state of Massachusetts is changing that dynamic with its proposed disposal ban that will ban C&D material that has not been through a recycling center from being sent to a landfill. Costello praises the way the Massachusetts Department of Environmental Protection (DEP) has handled the development and moves to implement the ban. "The process the DEP has gone through has been open to industry. Contractors and recyclers have been involved from early on. We have been shown how to comply. So this process will assure the ban will be successful," Costello believes.

Such a ban is the future, he says. "It is a valid concept" that will only be the way demolition contractors will have to do business. And, anyway, he says, it is already the way his company is accustomed to handling material at the jobsite, so Costello Dismantling is ready for that future. C&DR

The author is associate publisher of Construction & Demolition Recycling and executive director of the Construction Materials Recycling Association. He can be contacted at turley@cdrecycling.org.

Explore the May 2004 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- Greenwave raises revenue but loses money in Q2 2025

- Recycled steel prices hold steady

- John Deere launches ‘Building America’ excavator contest

- Triumvirate Environmental acquires Environmental Waste Minimization

- Coastal Waste & Recycling expands recycling operations with Machinex

- Reconomy acquires German-based GfAW