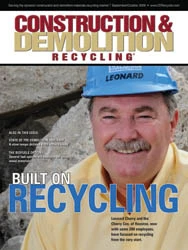

The recycling roots of Houston’s Cherry Cos. began in 1952, when members

of the Cherry family established a business to move homes intact from one location to another, addressing the re-use aspect of recycling from the start.

Over the course of the next six decades, the company started by Carl and Barbara Cherry and passed on to the next generation, has expanded into a number of recycling-related business sectors.

In 2009, Leonard Cherry, Carl and Barbara’s son, helps guide a family of companies that demolishes buildings, recycles a large percentage of the materials generated and crushes large volumes of concrete and asphalt for customers throughout the South.

ROCKETING FORWARD

The city of Houston has enjoyed the benefits of being a business hub for the energy and aerospace sectors, two industries that have boomed (although occasionally hitting a bust cycle) in the past several decades.

As the energy, petro-chemical and aerospace sectors brought new construction and development to Houston, the booming construction scene also entailed some demolition work.

For the Cherry family, residential demolition was a logical next step for their company, followed by an increasing amount of commercial demolition work.

CHERRY COMPANIES AT A GLANCE Principals: Leonard Cherry, president CEO; Rick Cherry, vice president No. of Employees: 200 employees working at up to 25 locations at any one time Equipment: Crushing equipment suppliers include Lippmann-Milwaukee, Powerscreen and Komatsu; mobile material handling and excavating equipment supplied by Komatsu and the Waukesha-Pierce dealership of Houston; processing and material handling attachments provided by Genesis, Stanley-LaBounty and Hensley Services Provided: Cherry Cos. is a collection of several firms, including Cherry Demolition, which provides industrial, commercial, interior and residential demolition services; Cherry Demolition Inc., which provides industrial dismantling and asset recovery services; Cherry Crushed Concrete, which offers fixed-site and portable on-site crushing as well as the production of recycled-content stabilized materials; and Cherry Concrete Removal, which takes up paved highways and dismantles bridges and then recycles the obsolete concrete, metal and other materials

Leonard Cherry remarks that his family’s involvement in residential work in such upscale Houston neighborhoods as River Oaks, Bellaire, West University and Tanglewood allowed them to meet people who also made commercial-scale decisions in Houston. "We were able to establish contacts with individuals who were able to make business decisions on larger projects," he says.

Carl and Barbara Cherry retired in 1985, and since then their four sons have taken different paths within the family’s business operations. Keith now owns and operates the house moving company and John runs a spin-off company focusing on asbestos abatement.

Leonard is the president of Cherry Cos. while Rick is a vice president with the company in charge of the industrial demolition division and safety programs.

Cherry Cos. has grown to include several corporate divisions involved in a wide variety (though related) of sectors:

• Cherry Demolition, which provides industrial, commercial, interior and residential demolition services;

• Cherry Demolition Inc., which provides industrial dismantling and asset recovery services;

• Cherry Crushed Concrete, which contains divisions within it: the Stationary Division, the Portable Division and the Stabilized Material Division, which adds cement to recycled aggregates to make a variety of sand, gravel and rock products used in road bases, paving surfaces, drainage materials and in other applications

• Cherry Concrete Removal, which performs road removal and dismantles bridges and then recycles the obsolete concrete, metal and other material. This division also houses Cherry’s roll-off and transportation divisions.

As of August 2009, the combined Cherry Cos. employs more than 200 people and by one industry estimate is one of the 10 largest demolition companies in the United States and one of the 23 largest in the world.

The scope of the company has changed dramatically since 1952, but Leonard says that a number of core philosophies have remained.

TONS OF PROGRESS

As the company founded by his parents has grown into the collection of firms known as Cherry Cos., their son Leonard says having the companies work together to win bids and provide customer service has been a major focus.

"Cherry specializes in projects in which our clients can benefit from the multiple services we provide," says Leonard. "These services include demolition, concrete removal, roll-off, aggregates, stabilized material and portable crushing."

PERSONAL TOUCHES Leading a family business that grows into a set of companies with 200 employees carries plenty of challenges, including how to maintain the family business atmosphere.

With several of those services involved in the recycling of demolition materials into secondary commodities, the Cherry Cos. has developed a considerable presence in Houston’s recycling sector.

Leonard Cherry says Houston-based Cherry Cos. has helped keep its family atmosphere in part by hiring trusted and recommended family members to help fill its employee roster.

“We have third-generation employees,” says Leonard. “We’re very proud of being a family business and our definition of family does not stop at the blood line. It includes our employees and those customers who have reciprocated with their loyalty.”

An enjoyable aspect for Leonard has been watching as both employees and their next generation of family members move up within the company. “We often find that the next generation of a family wants to perform a function that is different from that of their father or mother before them,” says Leonard. “The chain could go from truck driver to plant operator to safety supervisor. I think that’s one of the beauties of having a diversified company—there are plenty of career paths within this same family business, and each one is equally important to the whole picture.”

As a second generation leader, along with his brother Rick, Leonard is mindful of how to introduce the third generation of the Cherry family into the mix. “I have two daughters who both work in the business, and one son-in-law,” he says. “It will in part be up to them if they choose to run a business of this size and continue to guide it to grow and prosper. It’s an obligation not just to them and their families, but to the families of everyone who works here. Critical decisions have to be made as to what’s in the best interest of a lot of people.”

"A key component of Cherry’s overall environmental mission is to recycle its demolished concrete and steel into re-usable material," says Leonard. "Rather than add bulk to landfills, Cherry recycles as much construction debris as possible. By doing so, Cherry not only significantly reduces the amount of concrete and steel waste that ends up in landfills, but it helps preserve our nation’s natural resources. Cherry believes that a successful demolition and concrete crushing company must adopt solid environmental, social responsibility and sustainability initiatives," he adds.

This philosophy easily translates from words into mathematical form. "During the last one and one-half years, Cherry recycled 2,071,500 tons of concrete; this total equates to the reduction of approximately 1,000,500 cubic yards of landfill and the elimination of more than $11,530,000 in tipping fees (fees charged to dump trash at landfills and waste transfer stations)," says Leonard.

He continues, "During the same time period, Cherry also recycled 55,000 tons of steel, which has found new life in commercial projects in the United States and abroad."

Leonard estimates that on the typical industrial or commercial demolition project, Cherry Cos. is able to recycle from 88 to 92 percent of the materials generated.

There are environmental stewardship aspects that reach beyond the recycling activity, according to Leonard. "At Cherry, environmental consciousness is always a high priority. We strive to stay aware of existing environmental conditions and to understand what we as a company can do to protect our environment." On the health and safety fronts, Cherry Cos. "observes total compliance with OSHA (Occupational Health and Safety Administration) regulations and insists on 100-percent commitment to safety precautions at all times," says Leonard. "The fact that we have one of the lowest workers’ compensation modifiers in the nation testifies to the safety of our work practices. Cherry has an active safety team that inspects, rewards and educates our workforce on the most reliable safety procedures. We will only work with other companies willing to maintain our high standards for safe work practices."

SOLID REPUTATION

The company’s success in the Gulf Coast region has been noticed, as for several years it has been a nominee for the Ernst & Young Entrepreneur of the Year Award in the Construction and Industrial Services category in the Houston and Gulf Coast area.

A HOUSTON HIGHLIGHT Leonard Cherry, owner of the Houston-based Cherry Cos., received the 2009 Ernst & Young Entrepreneur Of The Year Award in the Construction and Industrial Services category in the Houston and Gulf Coast area. According to Ernst & Young LLP, the award “recognizes outstanding entrepreneurs who are building and leading dynamic, growing businesses.” A panel of judges selected Cherry and the award was presented at a banquet at the InterContinental Houston Hotel in mid-June. As a Houston and Gulf Coast area award winner, Cherry became eligible for consideration for the Ernst & Young LLP 2009 Entrepreneur Of The Year national program. Award winners in several national categories, as well as the overall national Ernst & Young Entrepreneur Of The Year award winner, will be announced at the annual awards gala in Palm Springs, Calif., on Nov. 14, 2009.

In June of 2009, the company found out that it was the 2009 winner in that category. Upon winning, Leonard stated, "We have been deeply honored by this outstanding recognition on behalf of our family, our employees and our customers. The true spirit of Cherry Cos. lies within our family values. This spirit of family extends to our employees and our customer base because they’re part of our family, too."

“I am deeply honored by this outstanding recognition on behalf of our family, our employees and our customers,” says Cherry. “The true spirit of Cherry Cos. lies within our family values. This spirit of family extends to our employees and our customer base because they’re part of our family, too.”

The Ernst & Young Entrepreneur Of The Year awards celebrated their 23rd anniversary in 2009. The program is designed to honor entrepreneurs who have excelled in such areas as innovation, financial performance and personal commitment to their businesses and communities.

“We are proud to recognize the achievements of Cherry,” says Doug Bogart, Ernst & Young LLP Entrepreneur Of The Year program director for the Houston and Gulf Coast area. “Winners of the Entrepreneur Of The Year award build leading businesses and contribute significantly to the strength of our region’s economy. Their success helps our area grow stronger.”

Regarding customer service, Leonard adds, "We are well-respected in our local community and within the demolition industry itself. We spare no effort to take care of our customers; the majority of our customers are repeat or referral customers."

Beyond the Gulf Coast region, Cherry Cos. has become known nationally in part because of the involvement of Leonard and others in industry trade groups. "We stay active with national, state and local trade associations," says Leonard, who currently serves on the board of directors at both Associated General Contractors Houston and the Construction Materials Recycling Association. Additionally, Leonard previously served as national officer and on board positions for the National Demolition Association.

"I firmly believe that involvement in trade associations that represent your industry is positive," says Leonard. "It gives you an opportunity to communicate and compare notes with counterparts in your industry who are not direct competitors in your market region," he comments. "As individual companies and as an industry, you become stronger by being able to share best practices."

The industry as a whole is served through trade groups, says Leonard, when it can present "a united front when forced to deal with legislative and bureaucratic issues in play—those that can affect you either positively or negatively."

Looking back, Leonard has found that initial trade group involvement allows a young leader to learn while involvement later on allows veterans to share their wisdom. "Typically, you pass a threshold, and in that first portion you have received more than you have given, but then after that threshold you give back."

THE NEXT CHAPTERS

In the past two decades, Leonard Cherry has helped build Cherry Cos. into what it is today with of a series of strategic decisions that connected several dots among the demolition, recycling, hauling and site preparation businesses.

One of Cherry’s first growth initiatives was the formation of its concrete recycling division in 1996. The division takes concrete from demolition sites to Cherry’s crushed concrete yards for recycling. Cherry formed its stabilized materials division in 2001 to add cement to recycling aggregates and sand to create a broader array of finished products. That division now operates from four facilities.

The concrete removal division began in 2003 to remove highways and bridges, thus creating an additional source of material to be recycled at Cherry’s crushing plants. (The success of this division has helped the fixed-site crushing division to grow from one site to the three now in operation in 2009.)

Leonard further reasoned that if debris is recycled at demolition sites and reused as on-site construction material, it decreases transportation costs, thereby reducing material costs by up to 40 percent. So in 2003 the company purchased portable concrete crushing equipment and began using it for on-site aggregates recycling.

Launching all of these concrete recycling operations has carried some risks, in part because start-up costs were high. The initial investment in 1996 was equal to 100 percent of the company’s net worth at the time. But the foresight and investments have paid off, as the company’s 200 employee workforce and its rank among the largest demolition companies in the United States testifies.

Leonard is not willing to tip his hand as to where Cherry Cos. may look for its next set of growth opportunities. "We’re planning our next set of moves—we believe our business as a whole still has an upside," he says.

The look back is also pretty intriguing to Leonard, as he considers the growth of the business and the roster of high-profile demolition projects in the Houston area. "It’s been one hell of a ride," he remarks. "The company has clearly grown beyond my early expectations. Back in the late 1980s, my brothers and I decided that our goal would be to change the skyline of Houston. Through our efforts in demolition, we have been successful in doing that."

The author is editor in chief of Construction & Demolition Recycling and can be contacted at btaylor@gie.net.

Explore the September 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- Greenwave raises revenue but loses money in Q2 2025

- Recycled steel prices hold steady

- John Deere launches ‘Building America’ excavator contest

- Triumvirate Environmental acquires Environmental Waste Minimization

- Coastal Waste & Recycling expands recycling operations with Machinex

- Reconomy acquires German-based GfAW