Despite the economy’s slower tempo in late 2008 and 2009, GreenCity Recycling LLC, Louisville, Ky., has managed to grow from a company of two employees to a full-time staff of 25 in just three years.

Joy Basu, owner and CEO, and Paul Schlich, president of GreenCity, are managing a company that is adding staff, increasing its fleet of rolloff trucks and has increased its processing capability to 300 tons per day of C&D material at a time when many other companies are downsizing.

OFF AND RUNNING

At Louisville’s nearby Churchill Downs race track, getting out of the gate with a clean start is vital for the horses and jockeys of the Kentucky Derby.

The tempo can be slightly different for entrepreneurs, with Basu and Schlich having chosen a slower roll-out of hauling and recycling services.

Basu became more familiar with recycling processes in the course of establishing Scrap & Waste LLC, a Louisville-based metals residue brokerage firm he founded in 2004 as a response to steel mill customers of his catalyst and chemicals business.

|

GREENCITY RECYCLING AT A GLANCE |

|

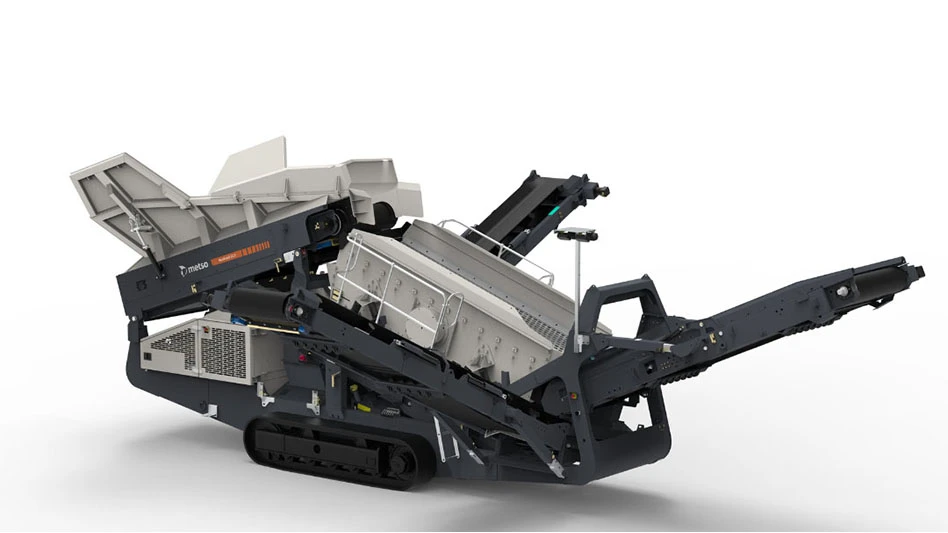

Principals: Joy Basu, owner and CEO (at left in the photo on the opposite page); Paul Schlich, president (on the right in the photo on the opposite page) Location: Louisville, Ky., serving six counties in Kentucky and three counties in southern Indiana No. of Employees: 15 full-time and from 12 to 20 part-time Equipment: Rotochopper grinder; Max-Pak baler; elevated manual sorting station system from Worldwide Sorting Systems; fleet of Freightliner and Volvo trucks; 140 rolloff containers; Fairbanks truck scale; forklifts and loaders Services Provided: Facility accepts mixed C&D materials for a tipping fee and sorts and processes materials; company also serves industrial customers and contractors by seeking out OCC, wood and plastics such as pallet wrap; hauling division serves some customer base of contractors and industrial locations |

The next year he incorporated a business that was originally called CDI (Construction Demolition Industrial Waste Recycling), but that subsequently began operating under the names GreenCity Hauling and GreenCity Recycling to emphasize the recycling focus of the company rather than being positioned as a waste hauler.

Having selected Schlich—a veteran of the insurance and retail product marketing industries—as company president, Basu bought GreenCity Hauling’s first truck in 2006 and selected a property that year to serve as a location for recycling operations.

"We moved into our current facility in June of 2006," says Basu. "After understanding the trucking quotient of our business, we started bringing back loads to our facility in January of 2007."

Throughout 2007 and 2008, Basu and Schlich added to GreenCity’s hauling fleet and processing capacity so that GreenCity Recycling could establish its footprint in the regional recycling sector.

At the beginning of 2009, GreenCity Recycling began soliciting and accepting loads from outside haulers as it strives to establish itself as an option for contractors seeking LEED points and for other customers searching for an alternative to the landfill.

TIPPED AND SORTED

Although GreenCity’s rollout of services has been phased in, the company selected a property that is large enough to accommodate the company’s growth as it occurs.

GreenCity operates from a 150,000-square-foot building located about three miles southwest of downtown Louisville.

|

A GOOD NEIGHBOR |

|

When Joy Basu and Paul Schlich selected a location on Beech Street in west Louisville, Ky., as the home for GreenCity Recycling in 2006, they were unaware that the location came with a very good neighbor. Directly across the street from GreenCity is Anderson Wood Products, a nearly 100-year-old company that makes wood millwork and component parts for the construction and furniture industries. It has not taken long for the two companies to discover ways to work together, with Anderson sending scrap materials across the street to GreenCity, and GreenCity providing feedstock for a line of fuel pellets made and marketed by Anderson Wood. GreenCity Recycling plays a supplier role to Anderson Hardwood Pellets, which also markets products under the name Kentucky Kernel Hardwood Pellets. Scrap wood can be generated, sorted, processed, pelletized and packaged, all within the two city blocks of the combined space of the two companies. "It really has been a perfect match," says Basu of the relationship between GreenCity Recycling and Anderson Wood Products. |

The building and its 7-acre parcel of land have offered plenty of space for both indoor and outdoor operations.

At the site, incoming loads cross the company’s truck scale and then can be tipped in one of several places.

Clean, source-separated loads, particularly of wood, can be tipped outside and staged near the company’s Rotochopper grinder, which is located outside under a metal roof. The company identifies incoming wood as either "A" (lumber or other natural wood) or "B" wood (particleboard, fiber board and other manufactured woods).

Mixed loads are tipped indoors, with trucks backing into a loading bay. The loads are tipped in a larger floor area where they can be spread out and initial sorting (selecting out both particularly desirable and undesirable larger items) can occur.

After this initial sort, loads are pushed toward GreenCity’s elevated sorting line, a 20-station system supplied by Worldwide Sorting Systems, Moberly, Mo. On the line manual sorters search for recyclable metal, old corrugated containers (OCC), paper, plastic, wood and other materials for which GreenCity has an end market. (Currently, this includes gypsum drywall, thanks to a recently identified and arranged end market.)

"Currently we are able to recycle between 65 and 90 percent of the material that comes in," says Schlich. That figure often varies depending on the phase of a construction project, notes Schlich. "It is interesting to see the progression of recycling through the life of the project," he says. "As the project progresses, so does the recycling percentage. Part of this is the natural progression of a construction project [less moving of dirt and more working with wood, metal, drywall and materials shipped in cardboard] and part of it is because the customer becomes more cognitive of recycling efforts and understands the model that we are trying to establish."

The company has also stayed true to its original CDI name by pursuing not only C&D materials but also OCC, wood pallets and other materials generated at industrial, warehouse and commercial facilities.

A LEED ROLE

Basu and Schlich market GreenCity Hauling and Recycling’s services from many angles, but with the knowledge that for most customers, the numbers must add up properly.

|

ONLINE SIDEBAR: BRIGHT OUTLOOK |

|

The sharp construction and manufacturing downturn that started in the third quarter of 2008 has affected GreenCity Recycling as it has most other businesses.

“Market conditions currently are reflective of the global crisis that we are in—in other words they are weak,” says Basu. Secondary commodity pricing that is down as much as 50 percent from the mid-2008 peak “has hurt the bottom line,” he notes.

Basu and Schlich are making their plans based on a slow-moving economy. “We do not see the prices of commodities coming back anytime soon,” says Basu. “We expect that this trend will continue for the next 12 months at least. Also, when they do start to come back they will come up slowly and in a very steady manner rather than the wild highs that we saw not so long ago.”

On the positive side for GreenCity, the commodity with the single greatest presence at its facility, wood, has not been in the same slump as metal and paper.

“One of the good things for us has been the wood pricing,” says Schlich. “It has held steady.”

Much of the company’s collected wood goes into a fuel pellet application at the Anderson Wood Products facility that is directly across the street. “We have no transportation costs to get the ground wood to the pellet-making facility; that gives us a big leg up in the wood recycling area.” Wood fuel pellets also have enjoyed solid demand, another factor working in GreenCity’s favor.

The challenges of the 2009 economy cannot be discounted, but Basu and Schlich are confident that their business model is ideal to work in tandem with emerging trends in the way companies conduct business and control their costs.

GreenCity Recycling is in the process of building its customer base to reach the 300 tons per day capacity of its equipment. Then, ideally, GreenCity can “explore other markets where the GreenCity Recycling model can be duplicated,” says Basu, whether elsewhere in Kentucky or in neighboring states.

Vertical expansion is also possible, he says, such as partnering with other companies like their current neighbor, Anderson Wood Pellets, by building small manufacturing units that can consume recycled material.

“In today’s business environment we have to be quick, nimble and able to meet customer requests in a timely manner,” states Basu.

“We believe in creating a passion for the business with our employees, and empowering our key employees with the proper tools and training for them to excel at their work,” says Basu. “A motivated workforce in turn makes it easier to create satisfied customers.” He summarizes the point of view by saying, “C&D recycling or the recycling business in general is no different than any other business—we are in the business of meeting and exceeding our customers’ expectations and making sure that they are able to continue their core business. That is the center of our business philosophy.” |

Schlich says that many of GreenCity’s potential customers "are recyclers at heart but not in their pocketbooks, so we are competing with the current entrenched system of wastefulness and a ‘disposable’ mentality."

Demonstrating to potential customers that their tipping fees can be lower is a key marketing role played by Schlich. "Sometimes, we have to show our customers the advantages of recycling in a model that is competitive with the disposable model that they have been used to," he comments.

To be competitive with landfills, though, involves operating efficiently, which is a full-time task for both Basu and Schlich. "Recycling is very equipment intensive, and this can become very costly very quickly," Basu remarks. As an example, he notes that it did not take long after purchasing his first few trucks to discover that maintenance and repair costs were going to be a much larger budget line item than he originally anticipated.

A focus on efficiency has allowed GreenCity to increase its processing capacity incrementally. Basu and Schlich say their sorting system can handle up to 300 tons per day, but currently the company is processing from 75 to 100 tons per day of mixed materials.

An emphasis on wood products (including, at times, scrapped baseball bats from a manufacturer in the region) has kept the company’s Rotochopper grinder busy. Accepting materials such as cardboard and plastic pallet wrap from industrial customers has kept its Max-Pak baler operating at a steady pace.

Also keeping GreenCity busy during the economic downturn has been its ability to tie into the LEED (Leadership in Energy and Environmental Design) certification system now commonly a part of new construction and commercial remodeling projects. "We are the first hauler/recycler [in Louisville] that is able to deliver LEED points MR2.1 and MR2.2," says Schlich. "We have successfully completed or are working on 14 LEED projects."

In tandem with employees that Basu calls "our biggest assets," Basu says that GreenCity will thrive as long as the company "makes every effort to meet our customers’ needs and do everything in our power to meet and exceed our customers’ expectations. A motivated workforce in turn makes it easier to create satisfied customers. We believe in customer delight." C&DR

The author is editor in chief of Construction & Demolition Recycling and can be contacted at btaylor@gie.net.

Explore the July 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- CDRA Conference & Tradeshow 2026: Addressing battery fire risks

- Darda equipment now available in North America

- Volatility wave hits copper pricing

- Volvo CE reports sales decrease in 2025

- Nasco-Op declares dividend

- CDRA Conference & Tradeshow 2026: CDRA honors annual award recipients

- Cedarapids to spotlight impact crusher at ConExpo

- Vecoplan appoints CFO