1. How does a robotic sorting system work?

Waste Robotics

Director of Sales

Within modern material recovery facilities (MRFs), a wide range of sensor-based technologies is deployed, with robotic sorting playing a central role. While designs can vary by supplier, most robotic systems rely on a common technological foundation. The process begins with advanced detection units mounted above conveyor belts. These units combine multiple sensor types to identify materials in real time. The data collected is processed by artificial intelligence algorithms that make rapid, informed sorting decisions.

Once materials are identified, software-controlled robotic arms equipped with specialized grippers execute precise pick-and-place actions, diverting targeted commodities into designated chutes based on facility-specific priorities. Consistent, well-distributed material presentation is critical as it directly impacts detection accuracy, pick rates and overall recovery quality.

2. What type of material preparation is required for effective robotic sorting?

Regardless of inbound material composition, successful robotic sorting depends on proper upstream preparation. The primary objective is to ensure optimal material sizing and presentation. This can be achieved through controlled handling by experienced excavator operators using grapplers or through preshredding equipment when higher throughput is required.

Following sizing, removal of fines is essential to maintain clean sensor detection of valuable materials. Screening equipment is therefore a recommended component of the process. Since robotic systems are most effective when targeting 3D, heavier items, adding wind sifters or ballistic separators after screening helps concentrate a dense, bulky fraction. This preparation strategy maximizes the robots’ ability to capture high-value materials at scale.

3. Which materials are suited to robotic sorting?

Robotic sorting systems are particularly effective when applied to the heavy fraction of the waste stream. Typical target materials include wood, concrete, bricks, inert materials, metals and rigid plastics. The integration of multiple sensor technologies—sometimes including near-infrared—allows robots to identify contaminants in wood streams and to distinguish plastics by polymer type.

In some applications, operators could choose to isolate specific materials to improve the quality of refuse-derived fuel in the residual stream. A key advantage of robotic systems is their flexibility: Sorting “recipes” can be reprogrammed quickly to adapt to shifting commodity markets, often by on-site operators.

4. How is a robotic system’s efficiency maximized?

Traditionally, many MRFs have been designed around single-shift operations, pushing maximum throughput within limited operating hours. Robotic systems, however, deliver their greatest value when integrated into extended operating schedules. By decoupling front-end material preparation from downstream robotic sorting, MRFs significantly can improve the overall efficiency of their operations.

For example, a front-end system consisting of preshredding and 2D/3D/fines separation could operate one shift at approximately 40 tons per hour, while a robotic sorting line— fed by a walking floor—can process the enriched 3D fraction at 10-20 tons per hour over 16 hours or more per day. This approach prevents bottlenecks on the tipping floor and fully leverages the robots’ capability to operate continuously.

5. How can human labor and robotic systems work together at a MRF?

Concerns about automation replacing human labor are common, but in waste sorting, robotics are best viewed as a complement rather than a substitute.

Robots excel at repetitive, high-volume tasks, allowing human workers to focus on higher-value activities. For instance, a robotic sorting line can be paired with a quality control station, where operators manage less frequent material types while also overseeing equipment performance and maintenance tasks.

Given the high labor turnover rates typical in the waste industry, robotic systems provide long-term operational stability on primary sorting lines. This stability enhances consistency, safety and productivity, while human expertise remains essential to ensure smooth, efficient plant operations.

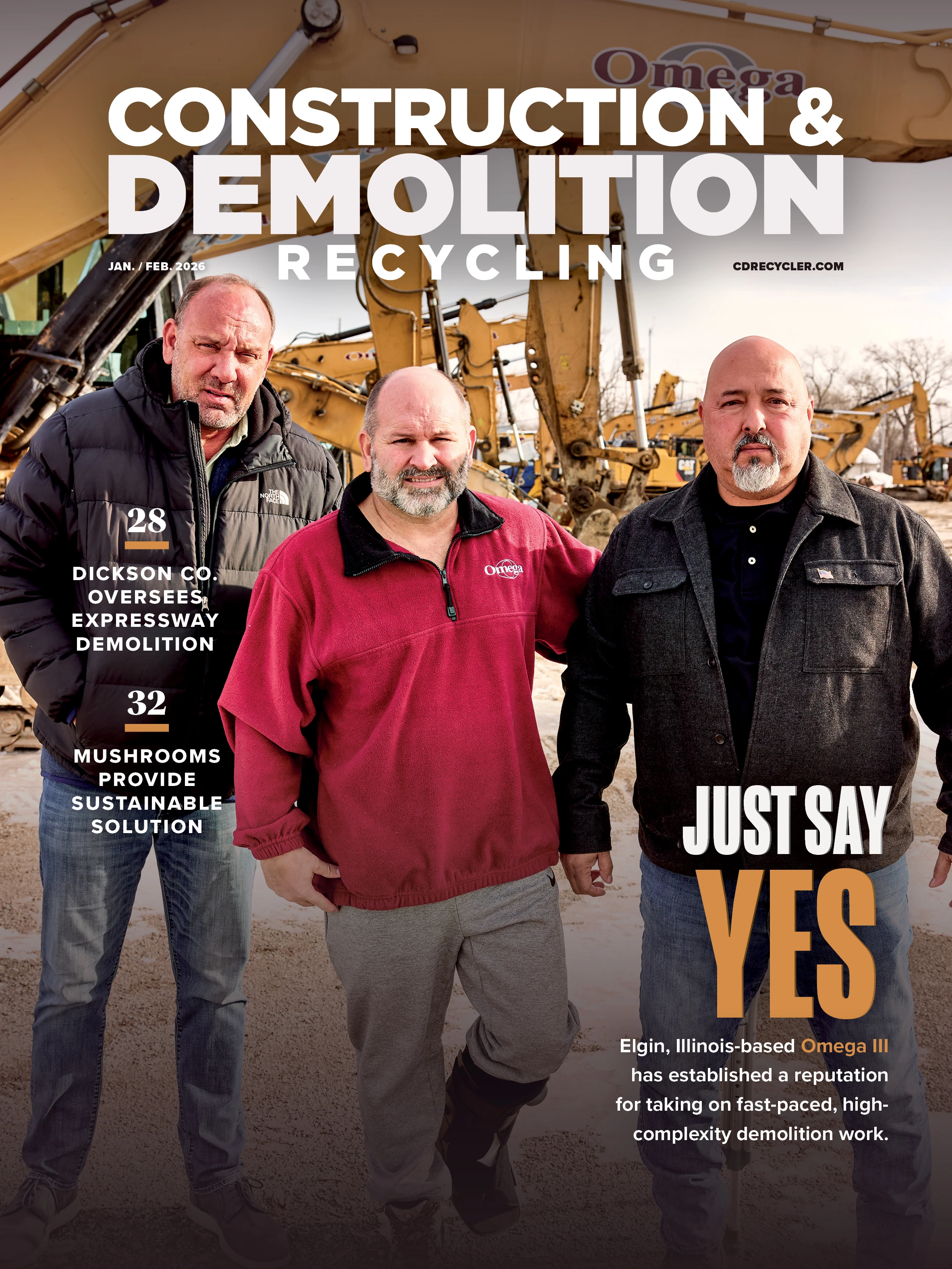

Explore the January/February 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Construction & Demolition Recycling

- Construction industry loses 11,000 jobs in February

- ALLU offers new crusher bucket

- Waste Pro files brief supporting pause of FMCSA CDL eligibility rule

- Des Moines project utilizes recycled wind turbine blades

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- Greenwave raises revenue but loses money in Q2 2025

- Recycled steel prices hold steady